Part Number: AM5716

Other Parts Discussed in Thread: TMDXIDK5718

Dear Experts,

We are using AM5716.

To determine the decoupling capacitors for each power supply, We referred to the schematics for the AM571x evaluation board TMDXIDK5718 (file name: AM571X_INDUSTRIAL_EVM_3M0000_PDF_REV1_3A.pdf).

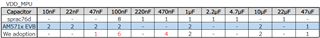

We ran into an errata i893 near the end of the design and made quality improvements for VDD_MPU.

At that time, we found Sitara Processor Power Distribution Networks: Implementation and Analysis (file name: sprac76d.pdf) and used it as a reference.

There was a difference between these two files about the decoupling capacitors.

We have two questions.

[Q1] Is it wrong to refer to the evaluation board when designing a circuit?

[Q2] sprac76d.pdf is listed in the WEB "Technical documentation", but it is not marked with a star.

Is it not possible to sort the technical documentation not marked with a star in order of importance?

It would be helpful if you could tell me because We want to proceed smoothly with the development of high-performance processors.

star = Top documentation for this product selected by TI

Best regards,

Kadowaki