Other Parts Discussed in Thread: SYSCONFIG

Tool/software:

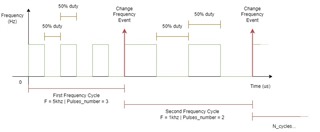

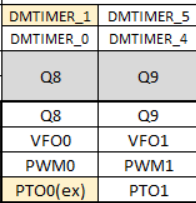

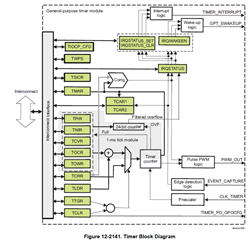

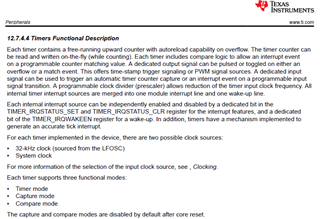

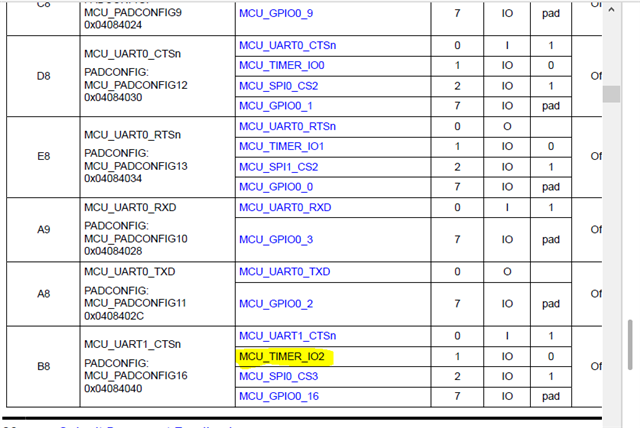

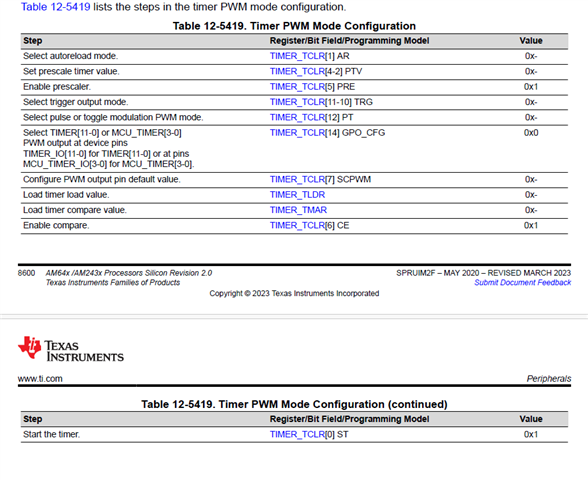

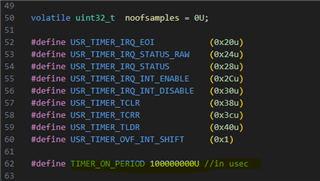

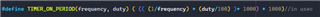

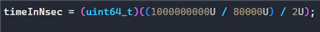

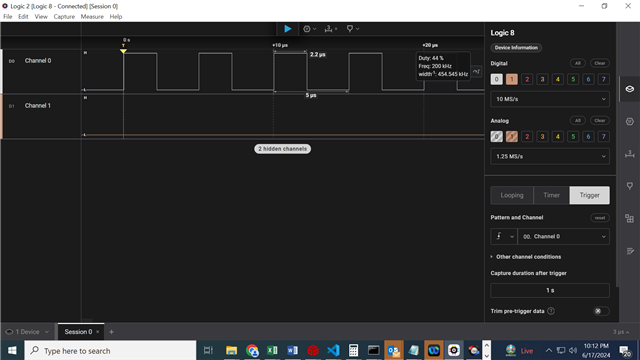

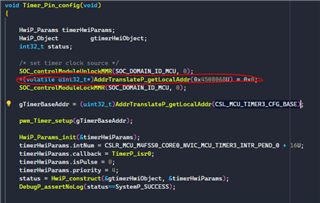

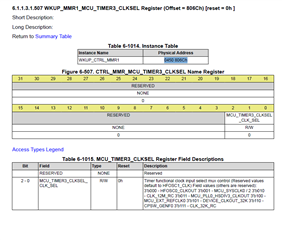

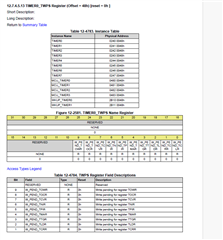

I am creating a fast output interface with the M4F, and I need both PWM and PTO signals. I was thinking about using counter compare for both, until I came across both APIs, both for timers and EPWM. But that's the problem, my demand requires that I use pure timers, without the EPWM modules to generate the PTO. EPWM will be reserved for PWM outputs. I checked the timer APIs and there is no function containing compare. By chance, there is this compare functionality but it has not yet been mapped in the API or generating the signals through the use of the overflow flag to toggle I/O at the determined frequency?

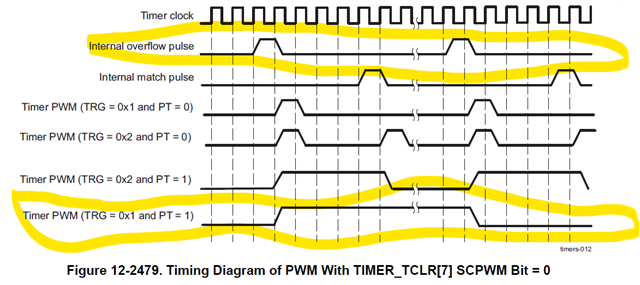

In this case, also referring to EPWM, I would be grateful if you could give a little insight into the relationship between the cycle time of a PWM, since, in the API, there are no functions like "Start_EPWM" or "Stop_EPWM", which left me a bit confusing, as it deviates from the conventional. What would be the option to start the cycle and end it? All the examples I tested led to the situation: the signal is born with the execution of the code and is never extinguished, continuing as long as the firmware on the M4F.

Yours sincerely,

Rafael Volkmer