Tool/software:

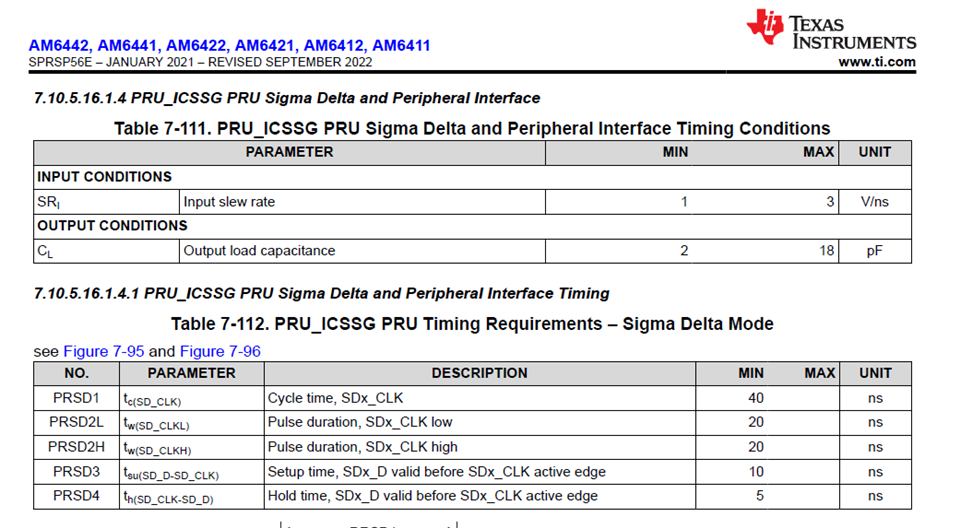

I'm working with a customer that is looking for some datasheet clarity around the Sigma Delta signal requirements. From the datasheet:

- Is this slew rate a requirement on the input signals to the PRU? I’m asking because the table is named “…Timing Conditions” as opposed to the next table which clearly states “…Timing Requirements…”.

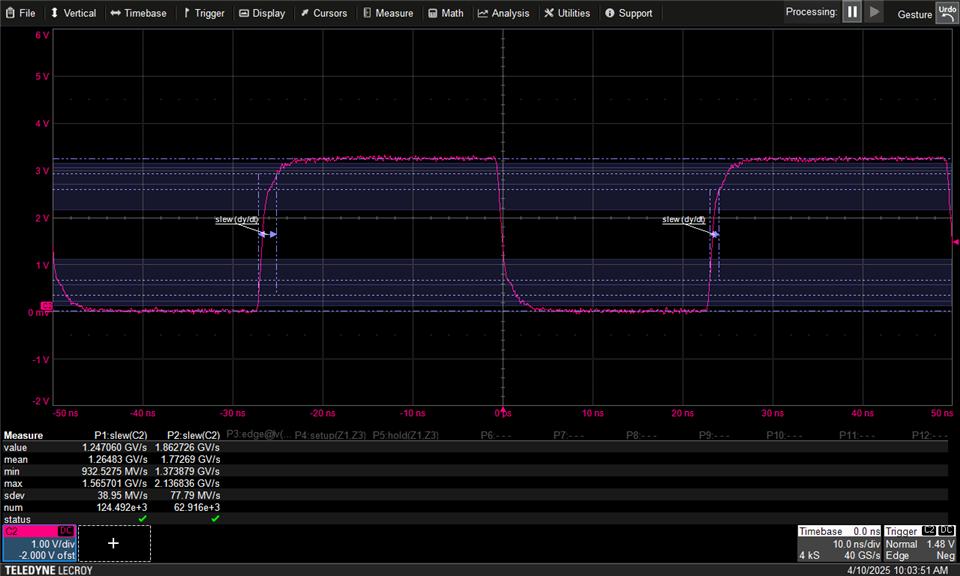

- If this is indeed a requirement, are there any measurement specification, like what percentage voltages of the edge the slew rate should be measured? My scope can measure a 10%-90% slew rate and a 20%-80% slew rate. Shown below is both the measurements on two edges. As you can see, there is quite a difference in the measured values:

Thanks,

Stuart