Tool/software:

Hi Expert,

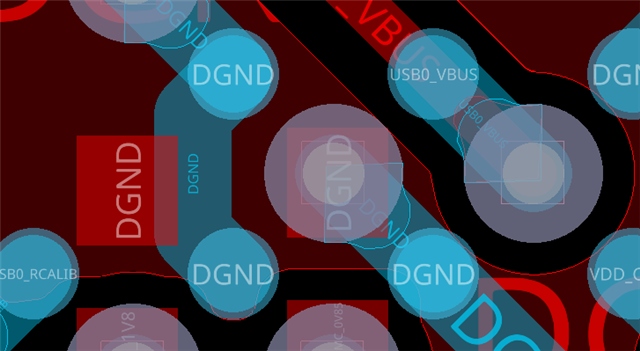

Customers reported that there are many 0201 decoupling capacitors on the back of our EVM using vias in the pad. Their factory has many concerns about this, as follows:

We are currently using POFV (resin plug hole + electroplating filling) + immersion gold process, but the electroplating flatness does not meet the welding requirements of 0201 devices; 0201 devices have small pads and low steel mesh thickness, and uneven electroplating of the holes in the pad has a great impact on it, which may cause cold soldering problems and cannot guarantee long-term reliability.

do you think this concern is make sense to you? do you have any suggestion to them?

BR,

Biao