Tool/software:

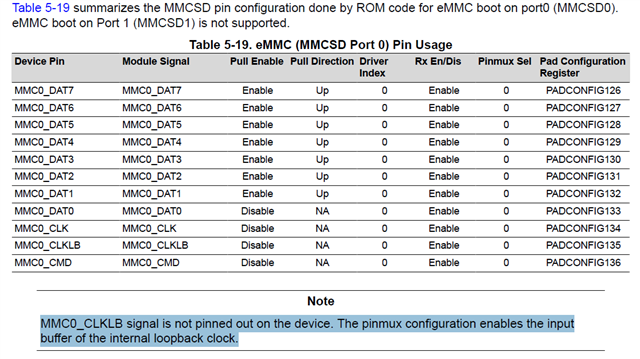

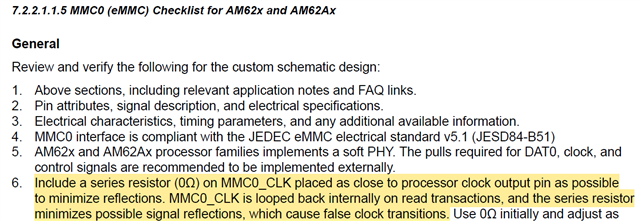

There is confliction on either schematic design guidelines and checklist:

https://www.ti.com/lit/pdf/sprad21

https://www.ti.com/lit/pdf/sprado3

#1. In Section 5.2.1.5, it highlighted MMCx and OSPI interface doesn't need series resistor on clock. But in later 7.2.2.1.1.5, it is highlighted to include one.

#2. Customer's question:

How the AM62x internally samples eMMC_CLK during eMMC read operations, and what state does eMMC_CLK need to reach for accurate sampling by the AM62x? This concern arises because the eMMC_CLK signal is sent from the source. When sampled at the source, the physical characteristics of the PCB dictate that the signal will inevitably have middle level steps, and the slew rate does not meet the AM62x's requirements.