Hi,

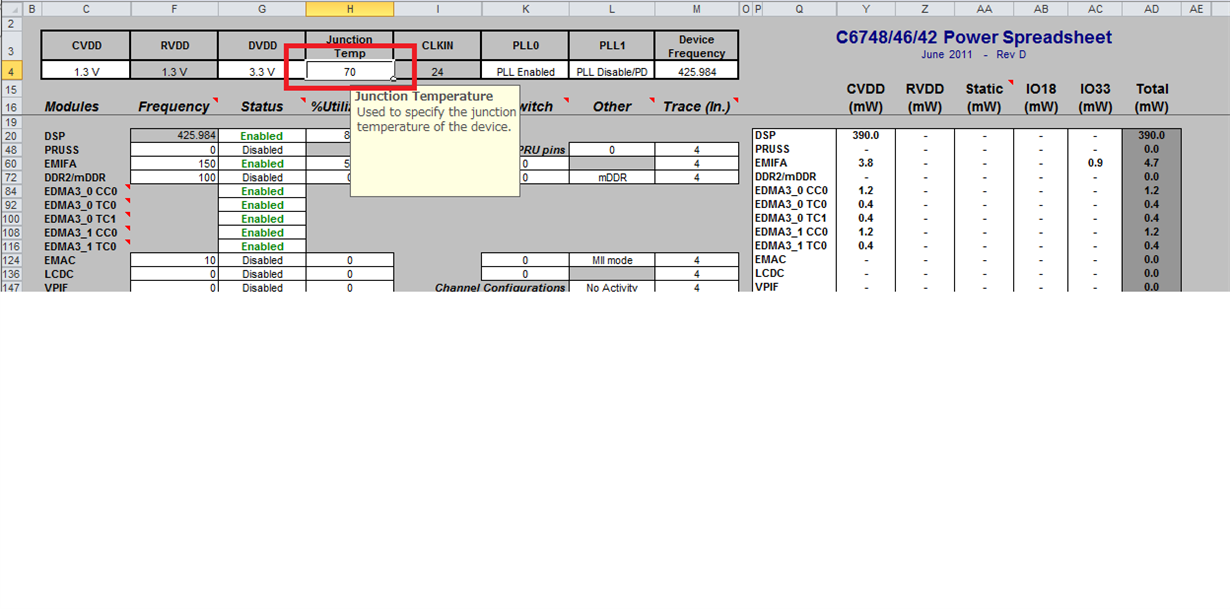

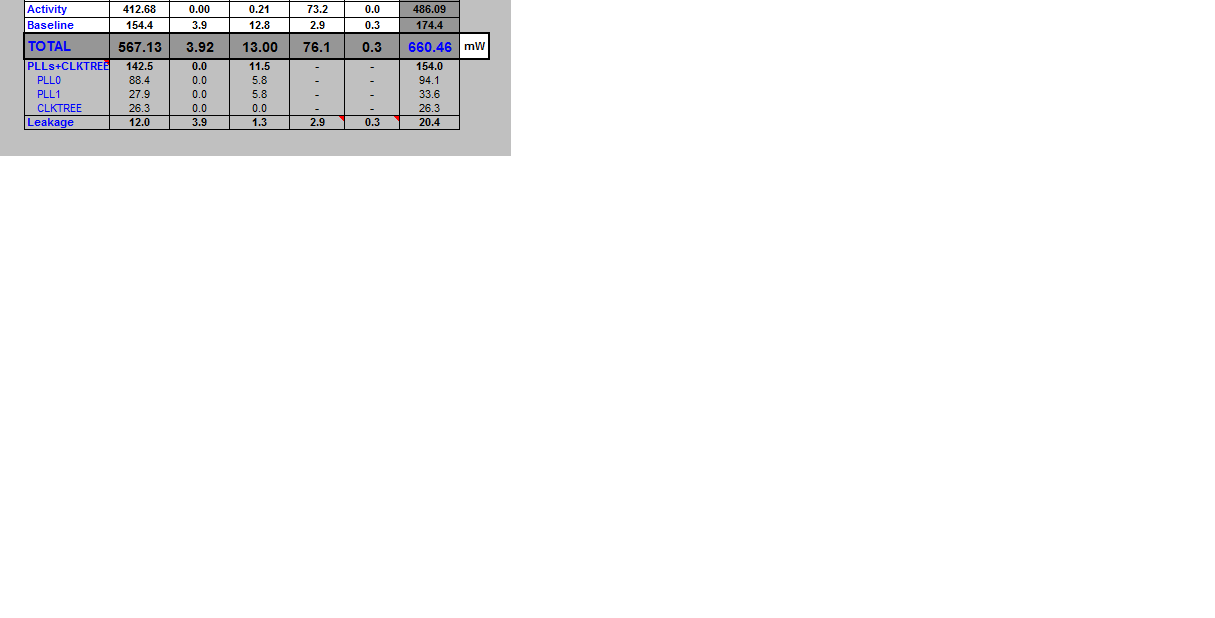

Just a short question. My customer is wondering if TI must have built your own board and validate the power consumption to issue the power consumption summary like this :

And now I'm getting some questions related to the test environment.

From my understanding, TI does not make such a test environment for power consumption summary sheet and this sheet has been made by considering the silicon/device characteristic. Is my understanding correct ?

Best Regards,

Kawada