Hi,

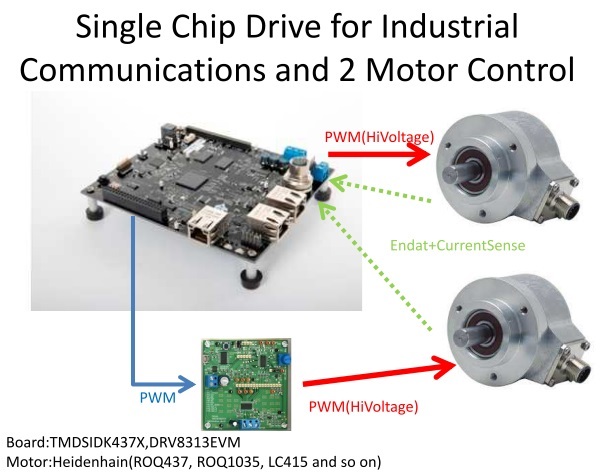

It's being considered whether AM437x is used as Ethercat slave device and 3pcs motro contorl.

In our case, we plan to use 3-phase BLDC motor with endat.

The one ICSS is used to EtherCat alve device and the other one is used 3x motor sequence with endat.

so, can AM437x cotrolled 3pcs endat motor?

It seems that the ISDK is supported up-to 3 encoders with identical part number.

What does it mean indentical number?(1GHz-device?)

SYSBIOS Industrial SDK 02.01.01 Release Notes

New In This Release:EnDat master concurrent multichannel support (up-to 3 encoders with identical part number @ 8MHz)

processors.wiki.ti.com/.../SYSBIOS_Industrial_SDK_02.01.01_Release_Notes

best regards,

kyt