Hello,

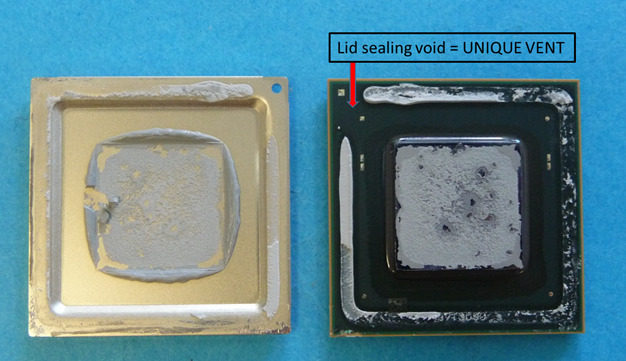

My customer is making a post-reflow washing which is mandatory in their manufacturing process. This washing involves some chemicals that remain trapped within the metal lid cavity. They observed that our FC-BGA package has a single vent opening in the lid which prevents all chemical traces to be removed. See the picture below.

I have seen that our FC-BGA reference guide recommends a no-clean soldering process, but that is not an option for my customer.

They ask if there is a reason why our package has a single vent opening, and whether we have a version with 2 or more openings. If we only have a package with a single opening, what is our recommendation to avoid chemical or moisture residuals after a cleaning process?

Thank you.

Best regards,

François.