Other Parts Discussed in Thread: MSP430F5528, TUSS4470

Good morning, there.

I am Minrak working in KIST and I encountered problem using ultrasonic transducer.

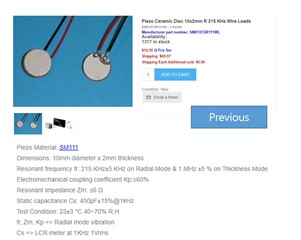

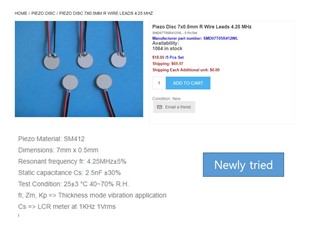

I want to decrease the water tank size so I tried decreasing transducer size from 10 mm to 7 mm.

Before changing tank size, I tried using the transducer size with 7 mm (DISC) instead of 10 mm (DISC) and filled water to 1 cm from the bottom of tank (tank thickness is 3 mm, tank geometry is shell with inner diameter of 12 mm, so higher than 10 mm).

All set-up was the same for 10 mm and 7 mm as well. But the water level is not correct for 7 mm and I know it as there is no TOF change when I increased water level from 1 cm to 2 cm.

For 10 mm, it works well.

So I am asking for help how to make it correct. What GUI setting or physical configuration change for 7 mm?

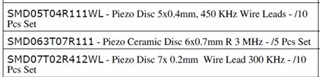

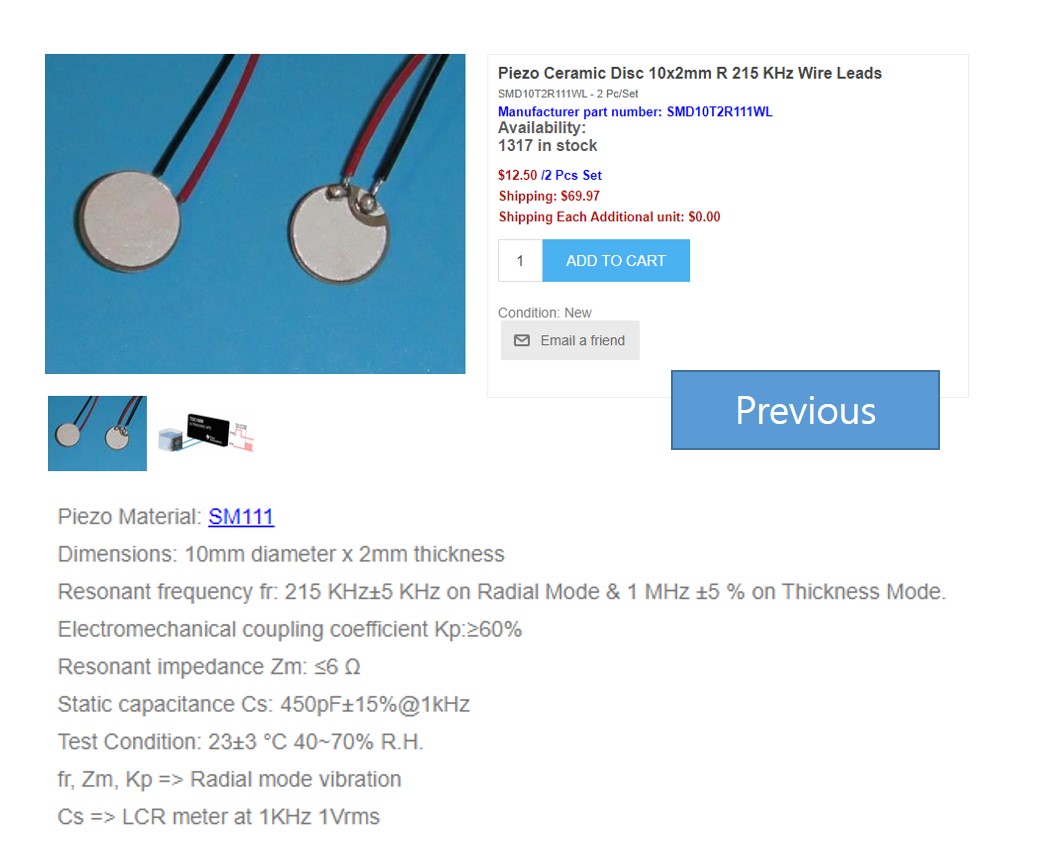

Please check the specs from the website links of STEMINC.

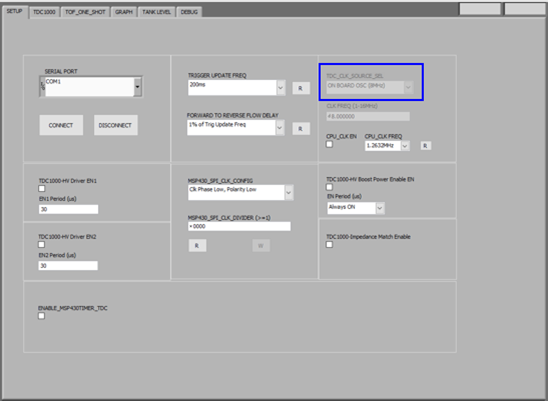

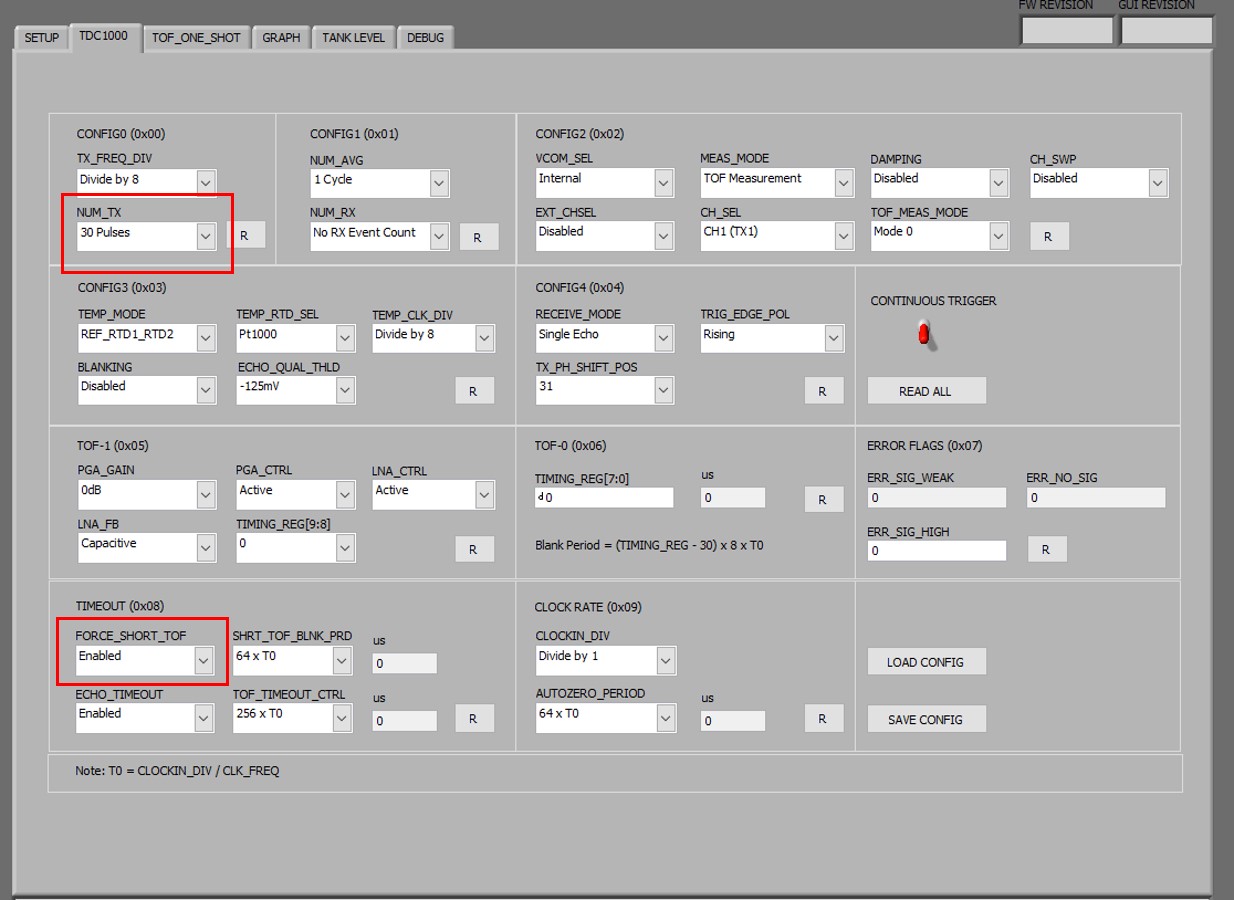

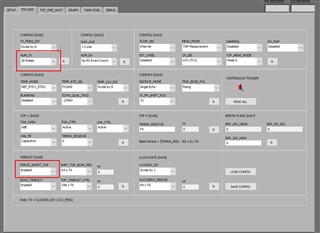

Here, I attach the specs of each (10 mm, 7 mm transducers) and GUI settings. The GUI setting was the same as in the last picture.

Previous (10 mm):

(Website link: https://www.steminc.com/PZT/en/piezo-ceramic-disc-10x2mm-r-215-khz-wire-leads-smd10t2r111wl)

Current:

(Website link: https://www.steminc.com/PZT/en/disc-7x05mm-r-wire-leads-4-mhz)

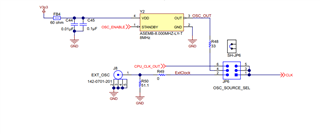

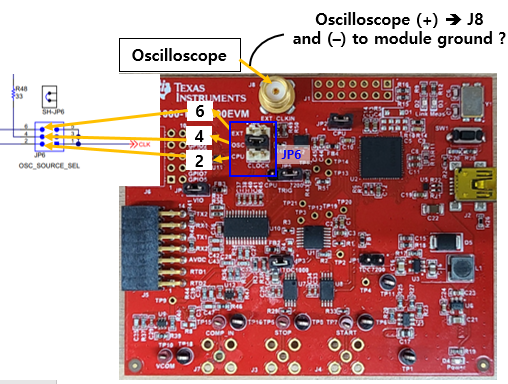

GUI setting

:

The most difference seems to be frequency and capacitance. But as you have more expertise in this field, could you please give me advice?

Best regards,

Minrak