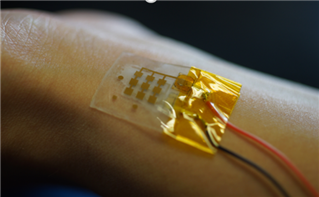

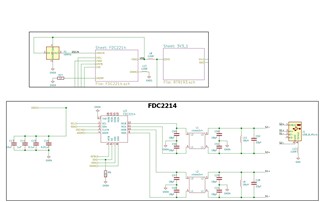

I have tried the default LC tank example for our blood pressure capacitance sensing application.

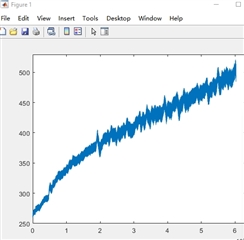

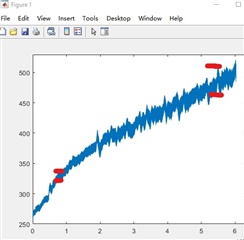

As attached picture the blood pressure capacitance amplitude becomes larger and larger, so I'm wondering if it has something to do with the LC tank value.

Our sensor's capacitance range is 100pf to 500pf. May I know if changing the LC tank value will help? And what's the exact L and C value you will suggest? Thanks!