Other Parts Discussed in Thread: TDC7200

Hi !

I'm Trieu Le from RYNAN Technologies Vietnam.

I have some questions about TDC1000 and TDC7200 drivers, please let me clearly understand about it.

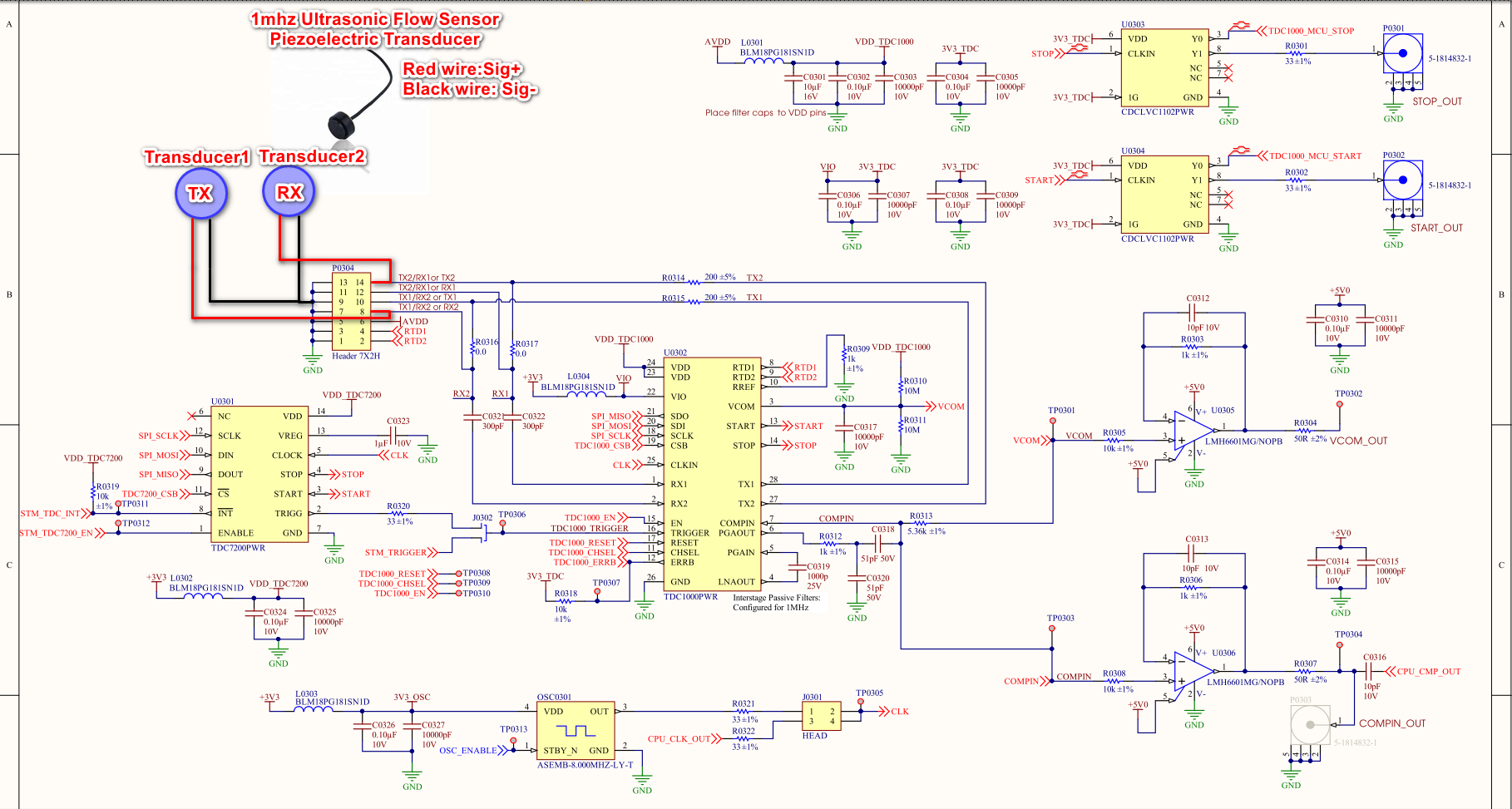

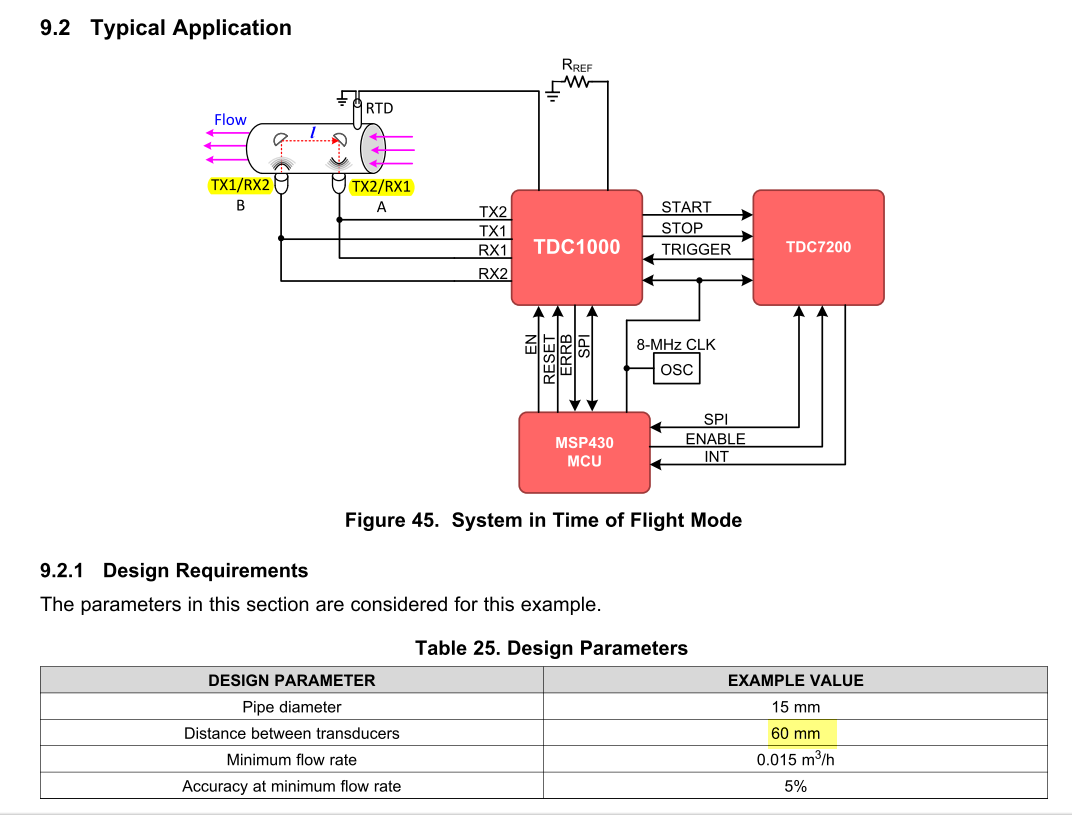

We have followed the reference design from TI based on TDC1000-TDC7200EVM development KIT.

And using 1 MHz transducer for our application, here is it: https://www.everychina.com/p-z52fca17-110907690-piezoelectric-transducer-micro-1mhz-ultrasonic-flow-sensor.html

In our application we want to install 2 transducers fixed about 0.5 meters apart, both of them submerged underwater. We want to measure the Transit-Time between 2 transducers.

Is this design suitable for our application?

Here are some questions I need your help:

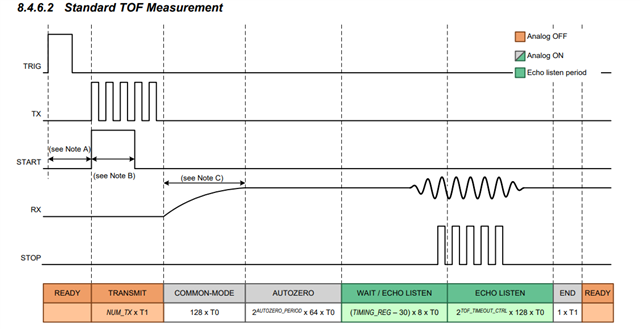

- I want to use 2 transducers to measure the Transit-Time between 2 transducers, which mode should be configured for TDC1000 in this case?

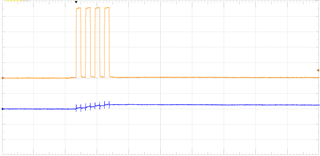

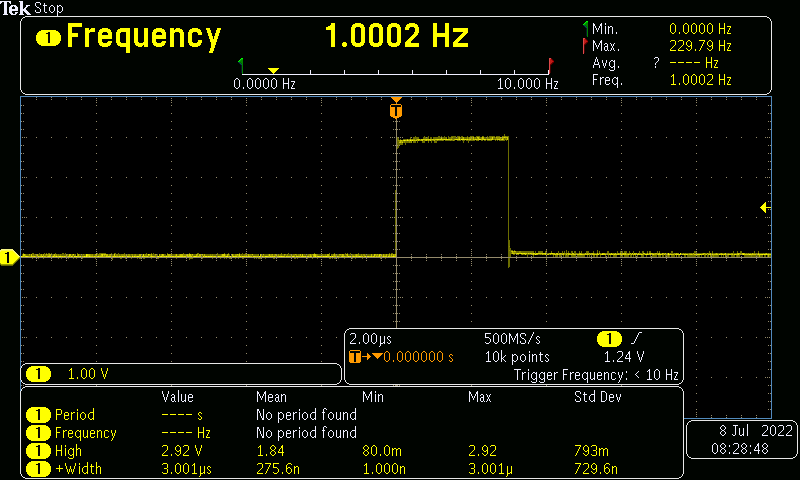

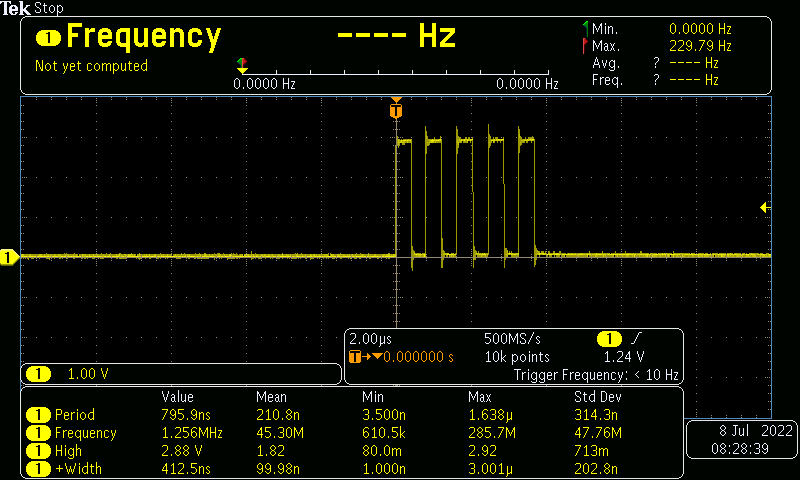

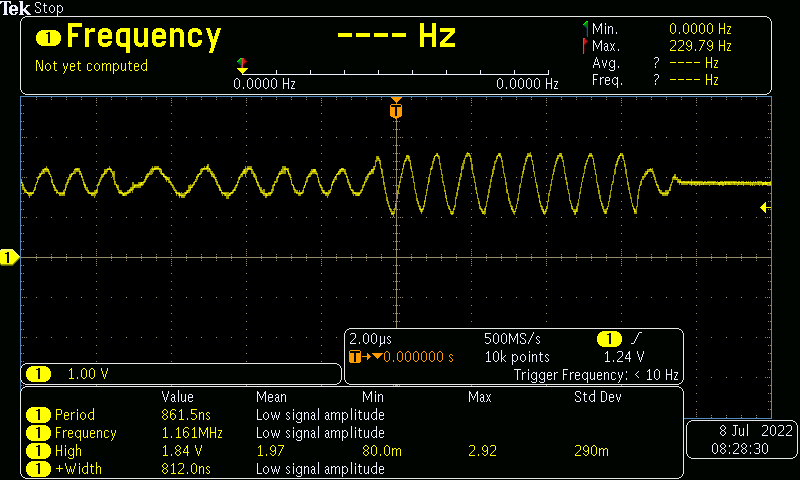

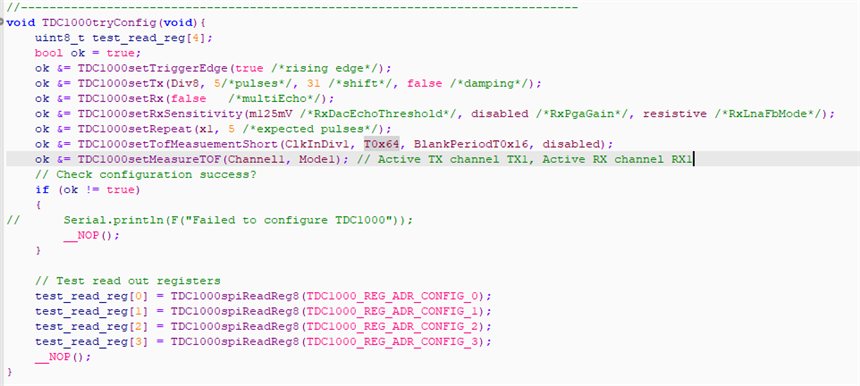

- I also tried to config TDC1000 working in mode 1 and channel 1 (Active TX Channel is TX1, Active RX Channel is RX1) then I connected only 1 transducer to RX1 pin, make pulse to TRIGGER pin every 1 second and I got the STOP pulses, and also got the waveform from COMPIN pin. My question is: Why is there a signal when I have only connected 1 transducer to pin RX1 (Pin TX1 is No Connected)

- Is this 1MHz transducer and this design suitable for Transit-Time measurements underwater?

Thanks !