Other Parts Discussed in Thread: TDC1000

Hi,

I need some help here, I had search thru the forum which related to my questions, I found out there are quiet a few thread didn't conclude or there is not solution can be found on the thread.

for example

TDC1000-C2000EVM: use TDC1000 + transducer ( ultrasonic ) to sense the water level of a plastic container from outside.

TDC1000-C2000EVM: Application using TDC1000 for measuring water level in tanks

TDC1000-C2000EVM: TOF value not changing with the water level

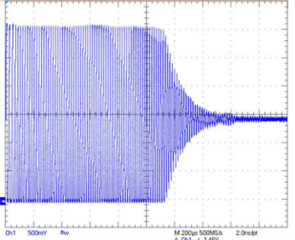

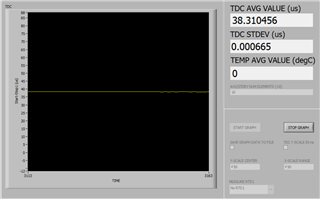

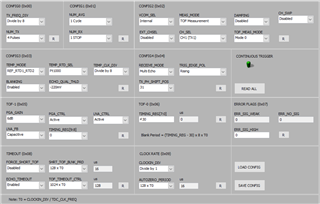

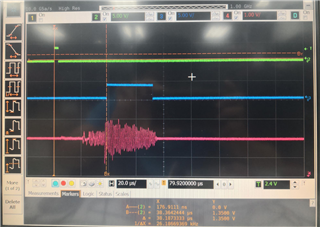

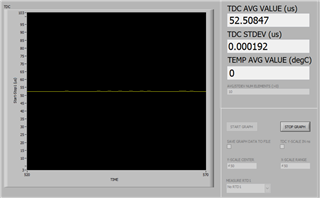

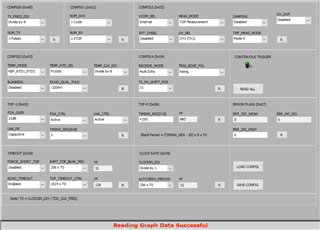

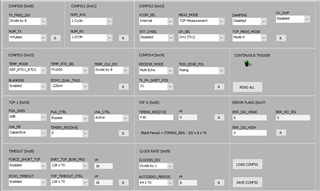

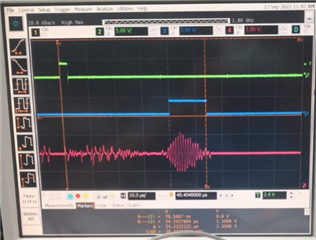

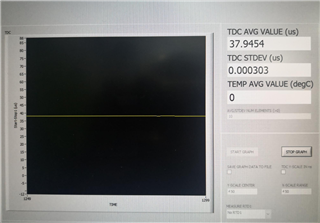

i had tried few type of containers but the all the TOF constantly remained around 38us. i am using SMD15T21R111WL. (1Mhz)

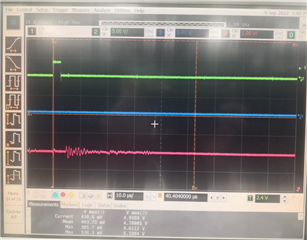

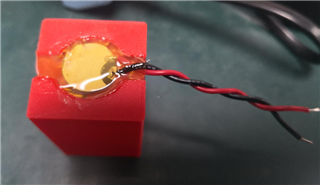

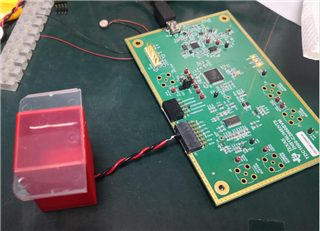

after that I print out a 30mm x 30mm x 50mm container as shown in the picture below and test it.

the TOF not changing no mater how height the water level is.

thanks,

Chin