Other Parts Discussed in Thread: LDC1614, LDC1312, LDC1314DIAL-EVM, LDC0851, LDC0851EVM

Hello Team,

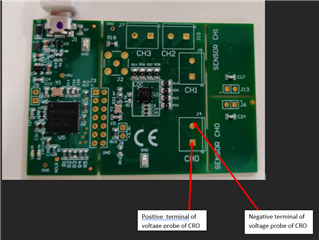

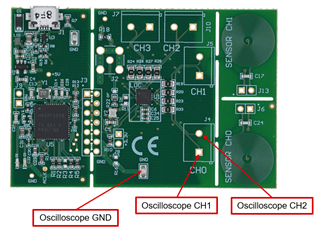

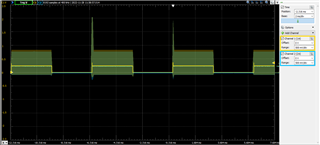

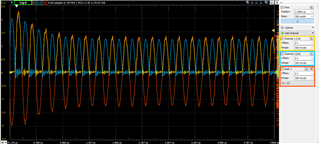

we had purchased evaluation board of LDC1614EVM. we have tested its basic features as per user guide.

As per LDC_Tools-ext51 we tried to understanding the calculation for spiral inductor design,LDC1614 config tool.

To understand in detail is there any document which show detail calculations of all these parameters mentioned in excel for LDC1614 eval kit.

like e.g calculation of sensor capacitance, inductance, number of turns etc.

Regards,

Sayali