Other Parts Discussed in Thread: TUSS4470

Good Afternoon,

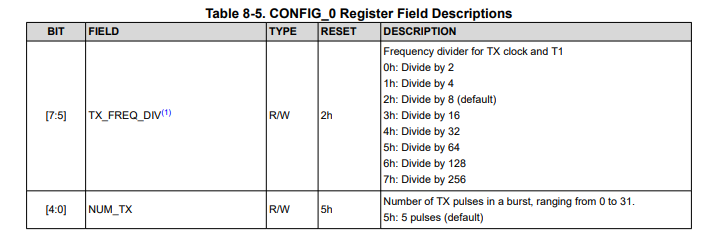

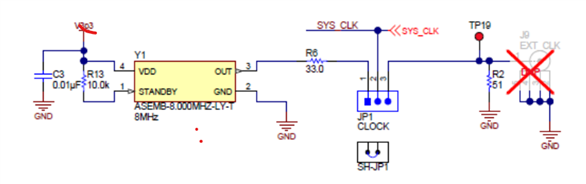

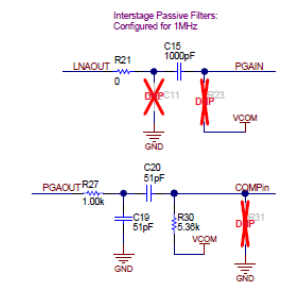

I am using a 3 MHz STEMINC Transducer (SMD25T07F3000WL) and I have it bottom mounted to a graduated cylinder for level sensing. Previously I was using a 1 MHz transducer but switched to 3Mhz in an effort to reduce beam spread, currently when I have it plugged in I am unable to get a reading. I was wondering what my configurations need to be changed to in the TDC1000 GUI application for this new transducer to function.