Other Parts Discussed in Thread: FDC1004

Hello John,

We're measuring a capacitor of about 200nF using a replica of the EVM board with own processor.

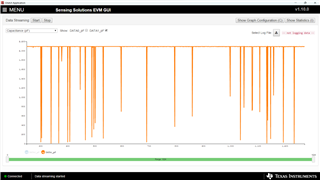

We noticed over time there is quite a fluctuation in readings. Already implemented a software floating median average algorithm of 100measurements, this is the output. It also swings a bit over time. Can you explain the swing/deviation and do you have any suggestions to get readings more stable over time? Our application is to observe fluctuations over time. We don't need a huge accuracy but stability would be required.

The image/data is logged over around 6,5hours outputting data of only channel 2 every 100ms

| min | 759509.6 |

| max | 810179.9 |

| ave | 787501.5 |

| st.dev | 6472.889 |

Looking forward to your reply, thanks.