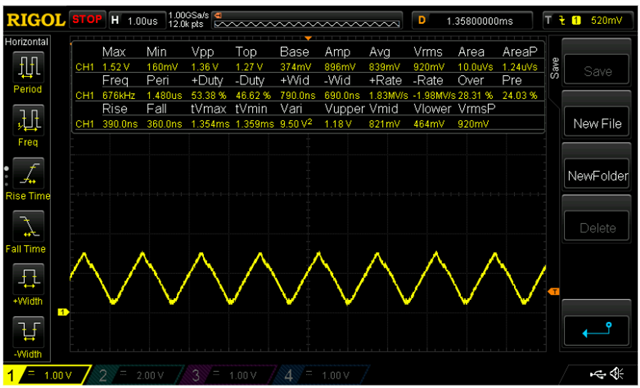

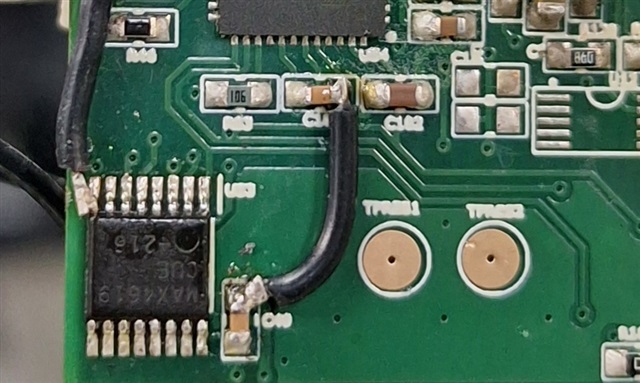

I have a problem with the active shield. I know from the datasheet the active shield signal should be the same with the excitation signal. But after i tried to connect a cable with shield, the active shield signal became a half for the amplitude, but the frequency was still the same. Could you guys elaborate about this issue?

-

Ask a related question

What is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.

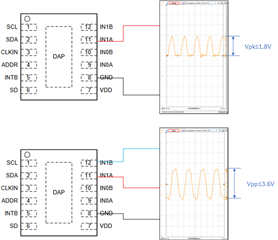

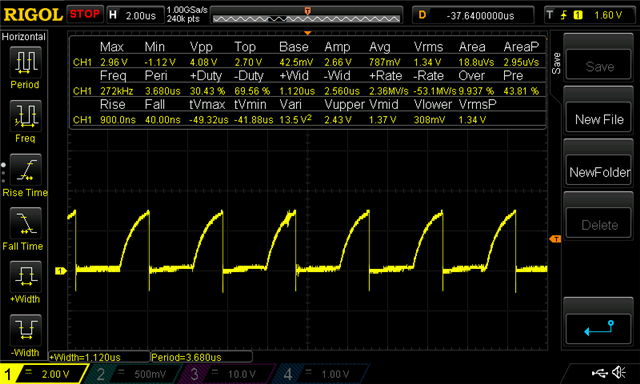

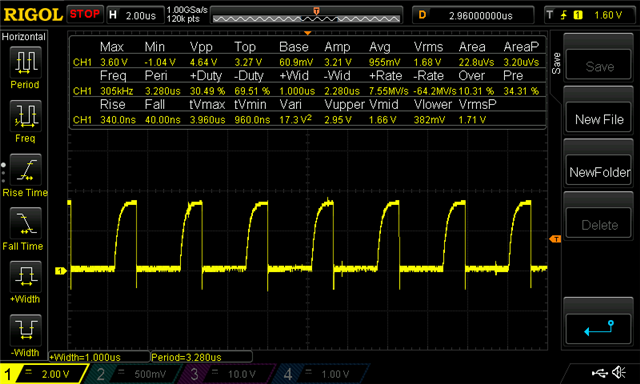

(left = the input, right = the output)

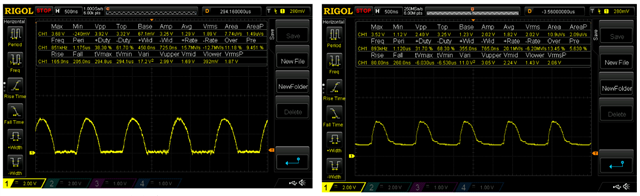

(left = the input, right = the output)