Other Parts Discussed in Thread: TMP1826, TMP468

Tool/software:

Dear TI Team:

We have LM95233 in our design, \

1. Could you pls review the SCH attached, thanks

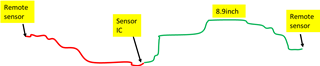

2. We will have the remote sensor far away from sensor IC, the plan path is as below,

one on the left and the other one is on the right, which may be 9inch faraway from sensor IC,

Is it OK?

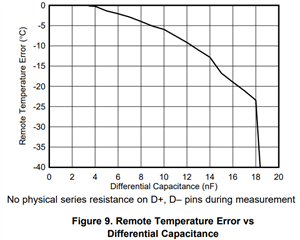

3. Could you suggest the distance between remote sensor(BJT/Diode) and Sensor IC(LM95233)?

And why has this distance restrict?

Best Regards

Lisa