Tool/software:

Hello,

The following are the images for your references.

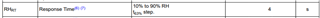

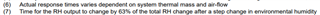

While testing the current circuit, the response time of the temperature and humidity is 50 seconds but in the datasheet of the HDC3021 it shows 4 seconds.

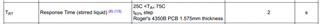

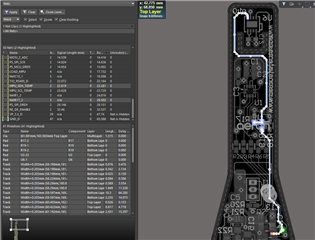

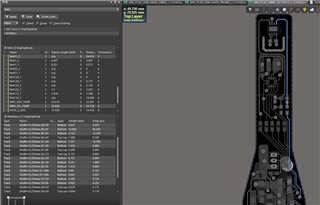

The images shows the track from sensor to Microcontroller, for SCL and SDA line

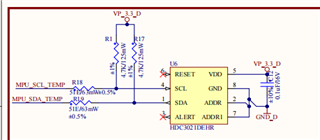

The above is the Schematic diagram the SCL and SDA line connected to the microcontroller.

I am not shielding the sensor with any material, currently testing an open PCB without covering the sensor, by comparing other comparative product the response time is very higher.

The teste is doing in the chamber, we suddenly place the sensor from ambient temperature to -40 degree. so the result is it shows the response time 50 sec to reach its 90% of reading.

Why so? do I need to modify the schematic or any layout change?

I had followed the layout guidelines and silicon user guide for the storage as well as assembly.

Let me know if any other input required from my end.