Other Parts Discussed in Thread: TUSS4470

Tool/software:

Hello all,

After trying out the TDC1000-C2000 EVM, we failed to get the required results on metallic tank level measurement.

We have decided to get the BOOSTXL-TUSS4770. We have started by using the provided 40khz transducer but have failed to get any good results.

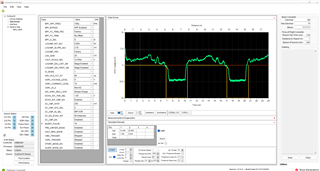

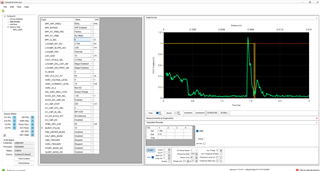

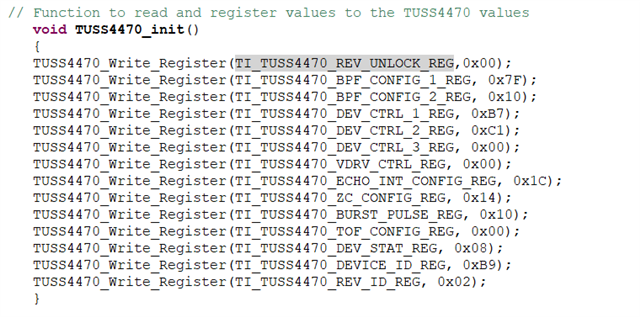

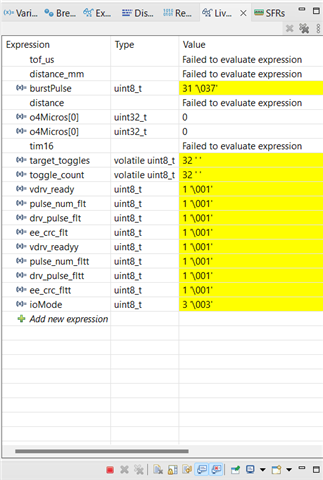

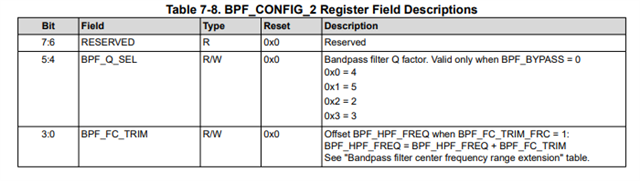

1. Below are the GUI settings we have been using. (Obstacle at 18cm)

2. Is there a significant reason why the SPI mode can't be changed in the GUI?

3. What are the recommended initial settings while working with this 40khz transducer.

By the way, we intend to use 1mhz transducer on a metallic LPG Cylinder at 1.2m for level measurement after these initial tests.

Regards,

Semyalo