Tool/software:

I have the same question as in the related question, which has not been answered til now.

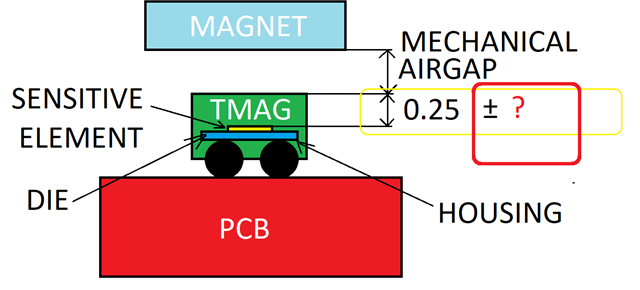

The dimension of 0.25mm has no tolerance on the datasheet. This dimension corresponds to the distance of the sensitive elements to the top surface of the housing.

The answer, that the position from the die to the balls is more accurate than 1µm doesn't help us.

I Think, that I need to explain better our problem:

The airgap (vertical distance between the sensitive element and the magnet) is in our case very small, because we don't use rare earth magnets, but elastoferrites, which deliver a weak magnetic field.

For this we face the problem, that depending of the tolerances of the mechanical assembly, we have a collision between the top surface of the TMAG and the magnet. We call this distance the mechanical airgap.

The magnetical airgap is calculated by the addition of the 0.25 dimension to the mechanical airgap. The tolerances of the 0.25mm dimension is needed to calculate the range of the magnetic airgap and only like this we can estimate the signal quality of the sensor over it's total operating range.