Tool/software:

Hi,

It took us more time than anticipated to get back to the issue so the previous thread got locked. Because of this I'm continuing it here.

The follow up questions to us that were presented:

Q: Can you share some details about the storage? Were these parts taken straight from a reel to PCBA then testing? Were they stored for any length of time in between those steps? If so, in what temperature and humidity conditions? Were they stored in bags, and if so, what kind? LDPE material, or metallized ESD bags?

A: The EMS had acknowledged MSL1 marking in the reel and no special process (dry chamber) etc had been applied. The components were taken straight from the reel for assembly by the pick and place machine of the EMS. For this batch of components the EMS was not able to provide information on the bag in which the reel was delivered in.

Q: Do you have the lot information or NIST IDs for these parts? I can check internally to make sure they looked OK during our production test.

A: Lot ID: 5030160ASC . We were unfortunately at this time not able to read the NIST IDs from the sensors, as that would require a change to the device firmware. Please let me know if this would provide you with key information.

Q: I see that this data appears to be about ~40%RH for the test condition, were any other RH levels evaluated? If so, do you see the same RH error at every humidity level checked, or does it change?

A: The humidity offset on these sensors seems to be quite stable. We've tested in varying conditions and the outcome is that the offset remains constant.

Q: Was no-clean solder paste used during the PCBA, and was any board cleaner used? If so, could you share the MSDS so that I may evaluate if any chemicals that can cause contaminations (which will affect RH accuracy) are present?

A: In our design, the sensor is mounted on a small pcb, and later the small pcb is soldered onto a larger board as one of the components. The ems confirmed that during the selective soldering, in which the small sensor board is attached to a larger one, it may be exposed to fluxes and solder. In addition to this, the sensor may be exposed to traces of chemicals used during the entire assembly process. The traces of chemicals that the sensor may be exposed to are:

|

3M 3764,Hot glue, general use 3M Quadratrack gluegun

|

|

Rapid 125 7mm hot glue Multi purpose 125 7mm

|

|

AIM, SAC305, Glowcore, Solderwire, Leadless

|

|

CRM SAC305 Leadless Solder, Selective solder

|

|

Alpha EF-6100 Wave Solder flux Wave-/selectivesolder

|

|

Loctite 3609 SMD-Glue

|

|

Alpha OM-338, OM-338-T SAC405 solderpaste

|

We have also been considering the baking & soaking process. As the sensors always seem to report elevated humidity values in comparison to the reference sensor, we are unsure whether the soaking, without the baking our make any difference. The samples have to our knowledge not been subjected to elevated humidities during their assembly or transport, which makes us think whether the offset is caused by something else, besides real moisture.

We just very recently had a smaller batch of samples manufactured by our ems, for which we requested that the sensors were hand soldered instead. We've not yet finalized the investigation, but the results seem promising.

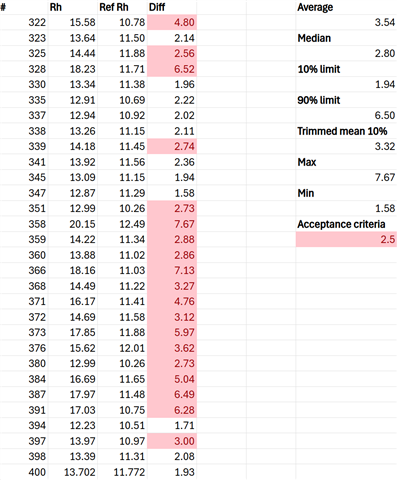

Below is an image of a chart where we tested 30 pcs of older selective soldered samples. We compared the humidity values reported by HDC3022DEJR to a calibrated humidity sensor. The # column are the sample IDs. The red cells indicate a sample which is 2.5 or more percentage units away from the reference value. As you can see, there's quite a lot that have considerable offset.

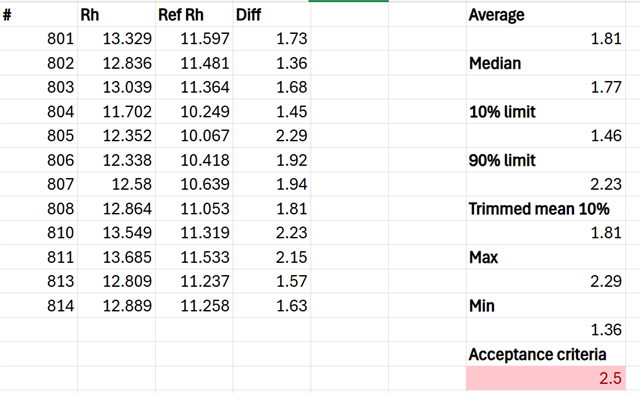

Below is an image from a newer hand soldered bach of samples. It's a smaller number of samples but it seems all of them report values closer to that of the reference sensor.

Do you think something like that could happen because of the change of the soldering process? Is there something else we could do to limit the chemical exposure during soldering?