I'm working with LMP91300 in order to detect a steel target between 0-3mm range. While using the evaluation board to program the DET_H and DET_L thresholds I took samples at 3mm for the DET_H and 3.3mm for the DET_L.

(from 1000 samples)

DET_H mean was 17027, Std Dev was 11. 74, Delta 73

DET_L mean was 16921, Std Dev 12.65, Delta 78

These values where written into the DET_H and DET_L FNL registers 0x73-0x76.

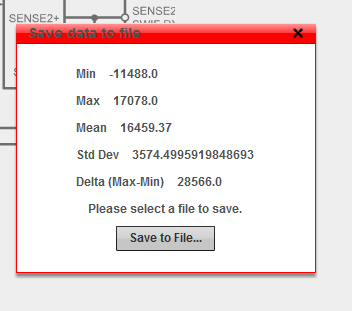

I then moved the target to 0mm from the sensor and started moving it away to verify that the target was detected properly within the 0-3mm range. When I reached 2.84mm the output started to flicker. I stopped and took 100 samples to see if the Rp value was varying between the DET_H and DET_L values and causing the flicker and I got this as my readings with 100 samples:

I've checked the other registers in the LMP and the values are all as we programmed them when we took the sample readings. Is there anyway writing the 0x73-0x76 registers could have caused this? If not then what are some possible explanations for this?

Thanks,

Cam