Other Parts Discussed in Thread: ENERGIA, MSP430F5529, MSP430G2553

Hi everyone,

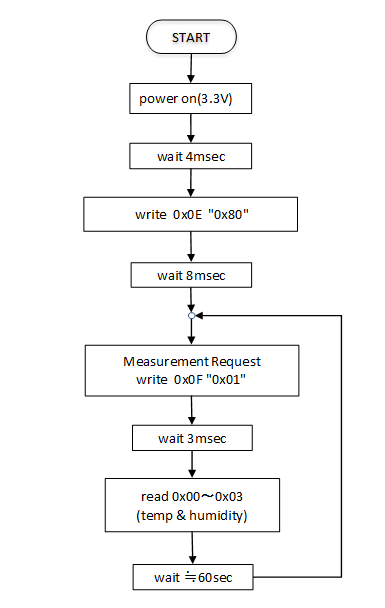

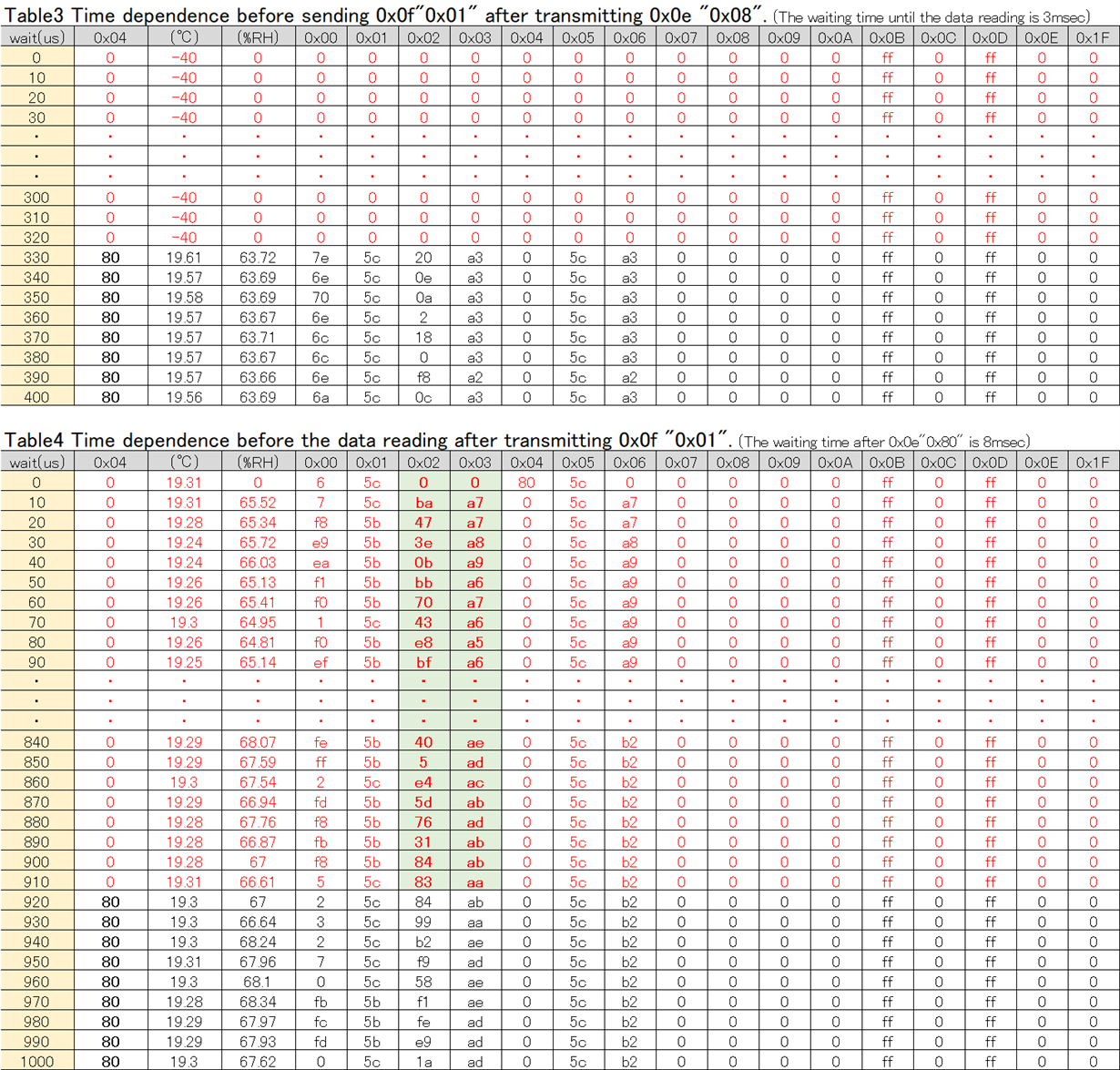

Please tell me for the phenomenon that happened during examination of the quantity of humidity drift.

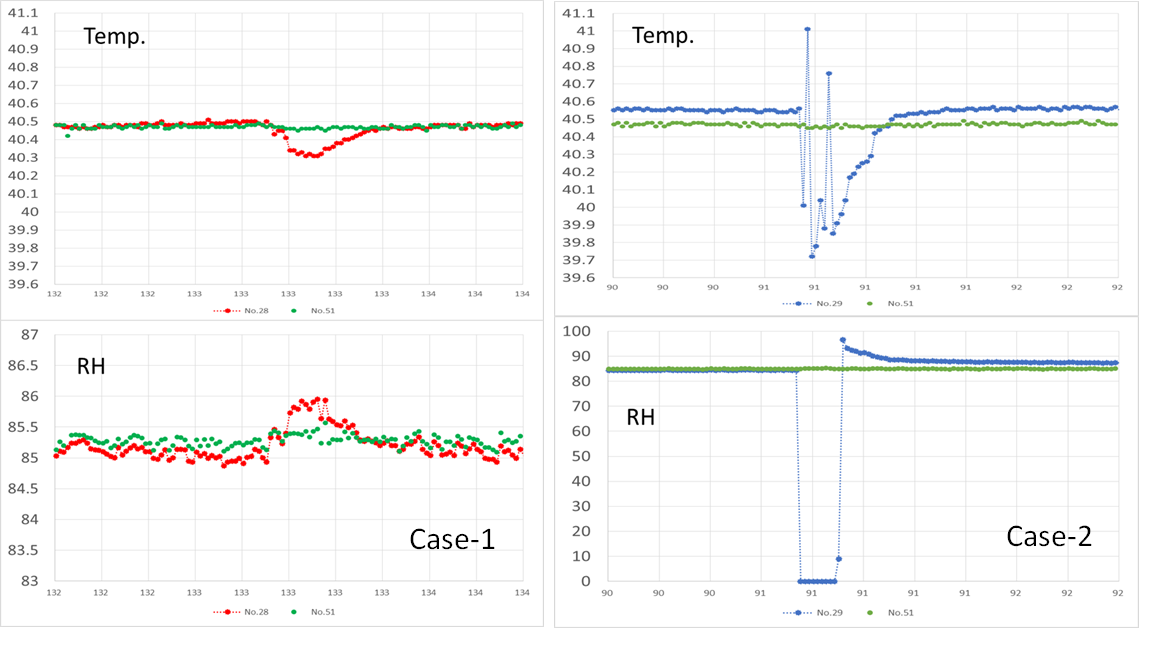

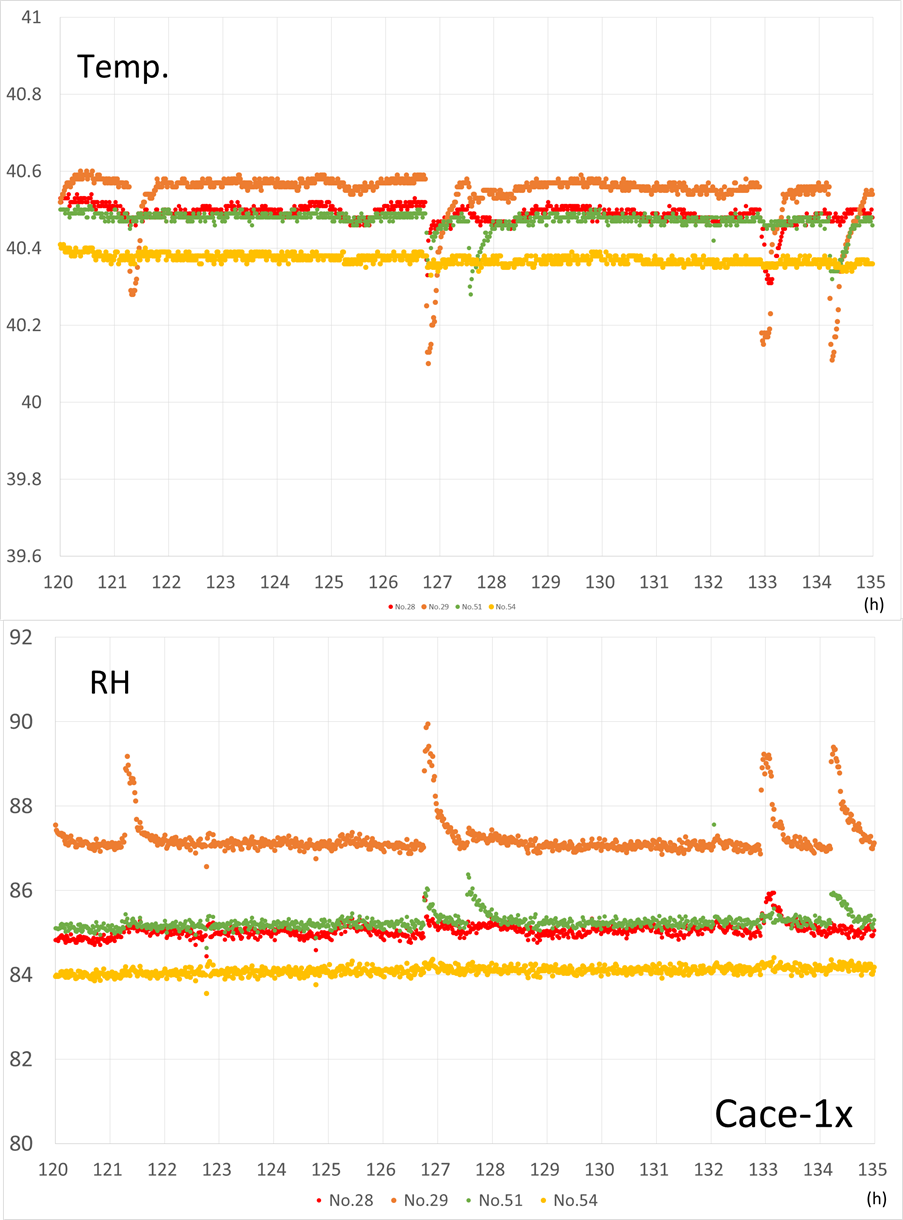

I set up 2 samples to a chamber and measured data every one minute.

(Case-1)

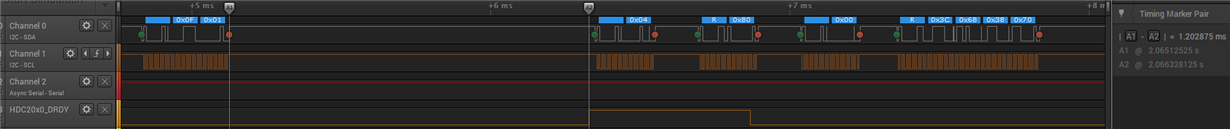

The phenomenon that temperature and humidity slightly shift is sometimes caused to be in the lower figure.

This phenomenon occurs several times for one hour.As this phenomenon occurs with each sample separately, there is not the cause to a chamber.Do you think that what happens with a sensor?

(Case-2)

For several minutes, humidity became 0%RH, and temperature became unstable.

I can measure other sample without a problem.What should I do to evade such a case?