Other Parts Discussed in Thread: DRV110, TPS272C45

Hi all.

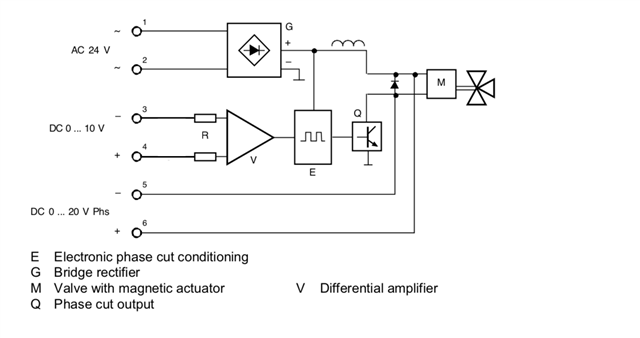

I need to design a new board in order to replace the original drivers for some HVAC's fluid control valves operating in the 0-20V DC range in phase cut mode. The steering method is an analog 0-10V DC that controls the amount of aperture of the valve in a quasi-proportional way (0-100%). I was thinking of using PWM method so I came across this thread and TIDA-00289 that as far I have understood uses only the enable pin to open/close the valve.

Could you please point me to the right direction to check if it can be done modifying the schematic?

I know it sounds a little bit vague but I need a starting point to begin.

best regards.