Hello,

I want to connect a mouse encoder, that is a LED light and a sensor to a CC2541 chip. Is this possible?

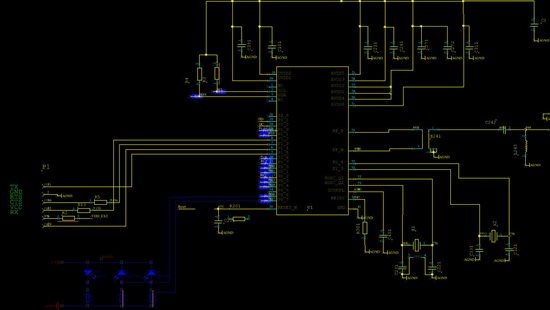

I have the reference design of CC2541 and I found a reference design of a mouse encoder. I want to join these two reference design. Again, is this possible? I have the reference design below. Can anyone help?

Reference design for CC2541

Reference design for the mouse encoder, with LED light and sensor. This diagram has a PIC chip, but I want to know whether if I can remove the PIC chip and connect it with CC2541. if yes, does anyone know how?

3058.reference design of mouse encoder.docx

thank you