Now i have familiar with Sensor Demo. If I want to use external Sensor with Gpio. I have gone through Some Doc. Steps For Reading External sensor.

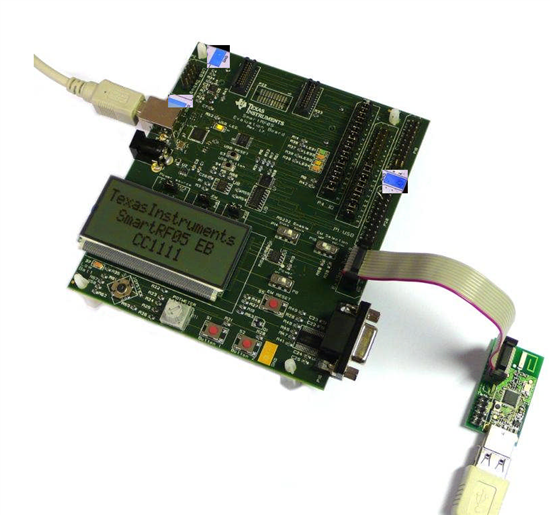

1)Connect sensor output to any digital i/o pin( P0_0 - P0_7). I found that, P0_7 is connected to pin 17. But in Smart RF 05 EB, there is two pin 17. one is P10 IO and P1 USB. Which should i have to connect?

2)Configure that pin as input pin.

for example i am P0_7,

P0SEL = 0x00;

P0DIR = 0x00;

APCFG = 0x80;(In which file of z-stack this SFR defined ?????)

3)HalAdcSetReference( HAL_ADC_REF_125V );

where adc_value in uint16.

These 3 step is enough, or need some more steps?