Tool/software: Code Composer Studio

Hi,

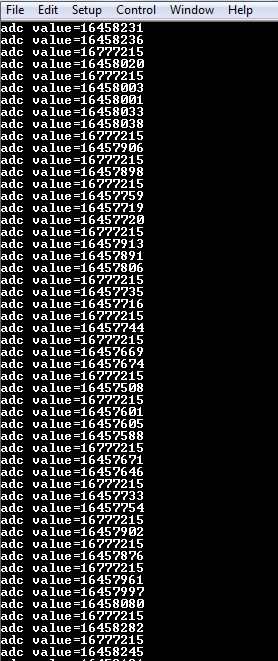

I have a custom board with ads1232 associated with a loadcell ,the digital values outputted from ADS1232 is measured by MSP430G2533.Now i just tried to observe data from ADS1232 with different clock provided from MSP430

1. Is there any suggestion about SCLK( i used 1ms to 10ms clock for one bit data in SCLK pin ,if reduce clock period i can detect small changes but doesn't get a constant value (167777215,16438215 etc).similarly there is no constant offset value )

2.what is the offset value that we obtained normally from ads1232 (without applying weight)?

3.Does the design need an external crystal connection in XTAL2 pin?

4.if the data is ready i start read data ,does the data get in rising edge of the clock?,does the second bit data receive when i provide another high low to the sclk pin (is it available in the rising edge of the sclk )?

5.i just provide 25 clock to the sclk pin ,as per the data sheet we expect that the data pin must be high but here i didn't get this why?,how to read continuous data from ads1232(please explain)?

6.What is the necessary delay between two set of 24 bit data?(is there any minimum or maximum) .

7.is there any sample code to obtain data from ads1232 ?

Aju