Other Parts Discussed in Thread: ADS1256, , ADS114S08, ADS1248

Hi

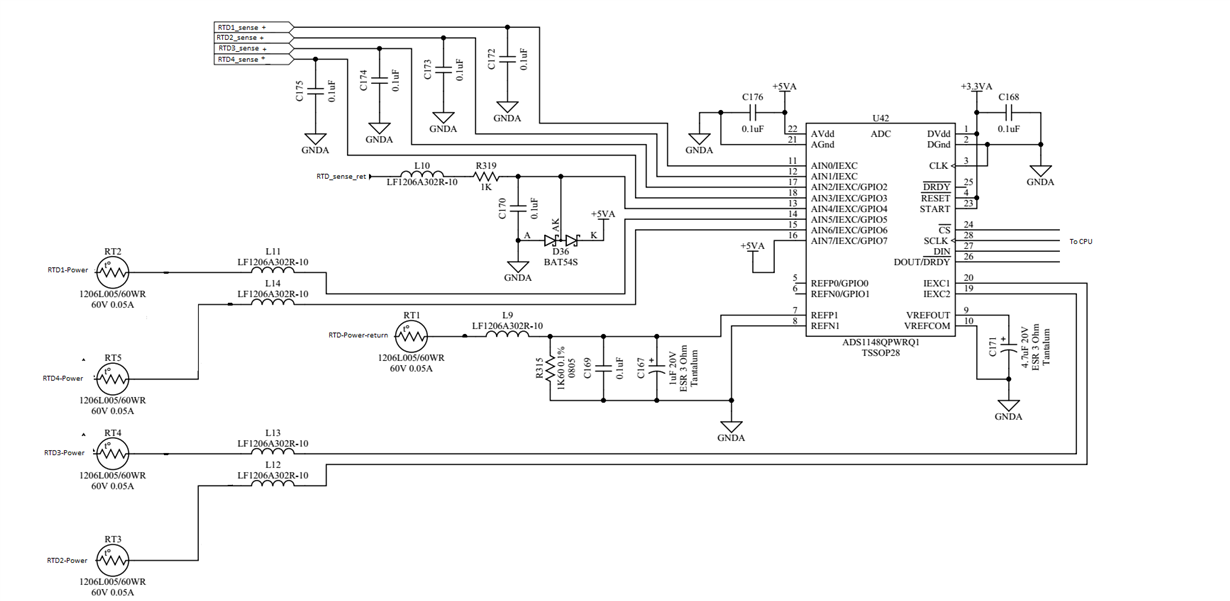

Are there some preconditions before executing the SELFOCAL command? I noticed when I am using an external reference and IDAC current, if the sensor (RTD in this case) is not connected, the calibration seems to fail, possibly because the reference is floating. When it happens, OFC registers get wrong values and internal temperature and voltage measurement (system monitor) is way off anything even remotely possible.

So do I need to set MUXCAL to 0b001 before sending the SELFOCAL command? Do I need to change REFSELT to use the internal reference?

And what about SYSGCAL? I don't have inputs supplying a full-scale input. But would setting MUXCAL to 0b010 be enough? Or I can't perform gain calibration at all in my setup?

For now I disabled calibration, since default values give acceptable results, but I would like extra precision if possible.

I should also add that I am used to the ADS1256 SELFCAL command, with which I never had any trouble.

I understand on the ADS1148 I need two commands to perform calibration, and that the gain calibration is not a "self" calibration command but is there any other difference?

thanks