Hi Champions,

My customer took F28027F to develop E-bike controller, they took lab5b and add some applications. Now they finished development, and need to take C2000 Gang to programming Flash, and need to converter .out to .hex for C2000 Gang, but they met a problem that:

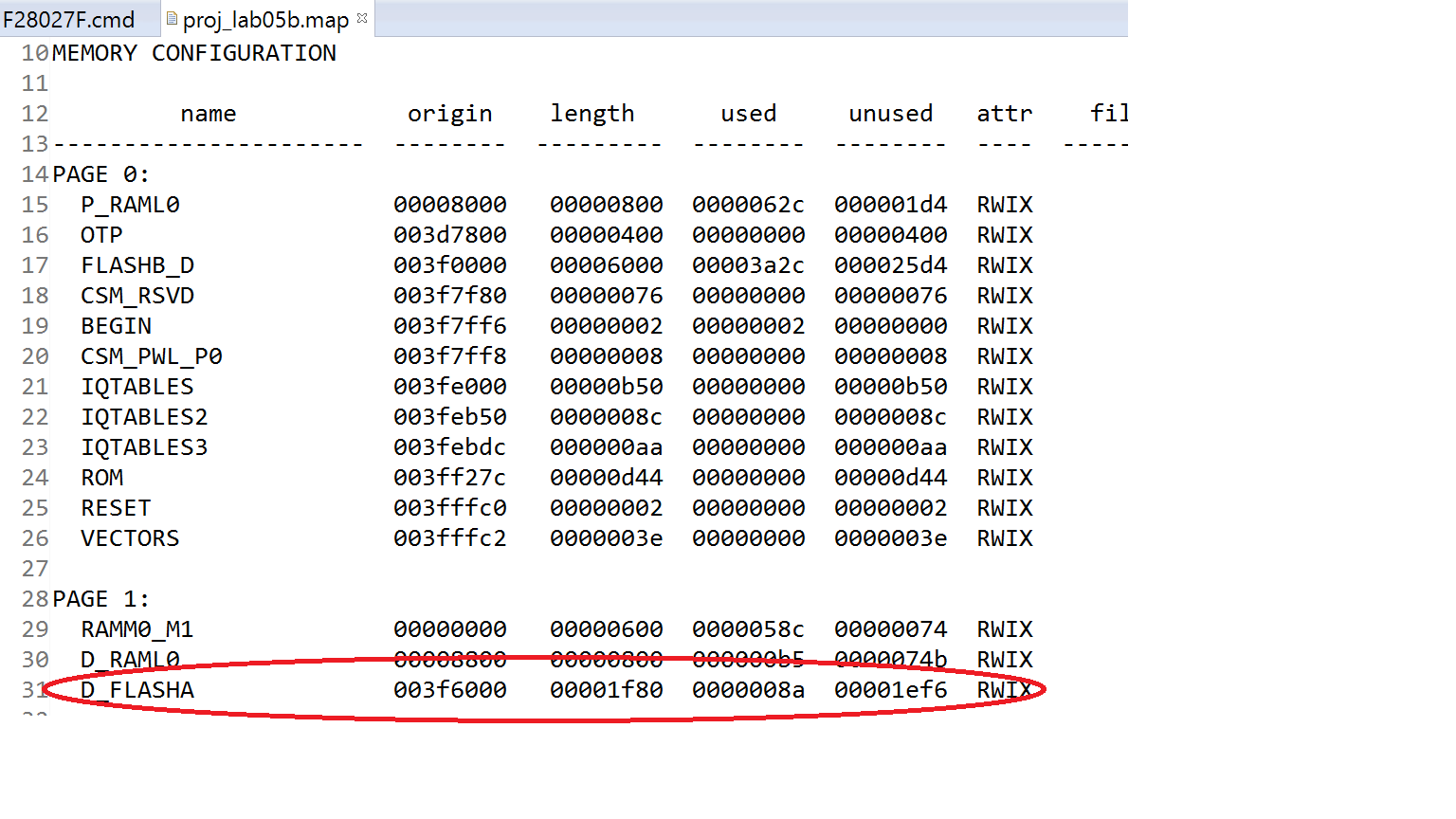

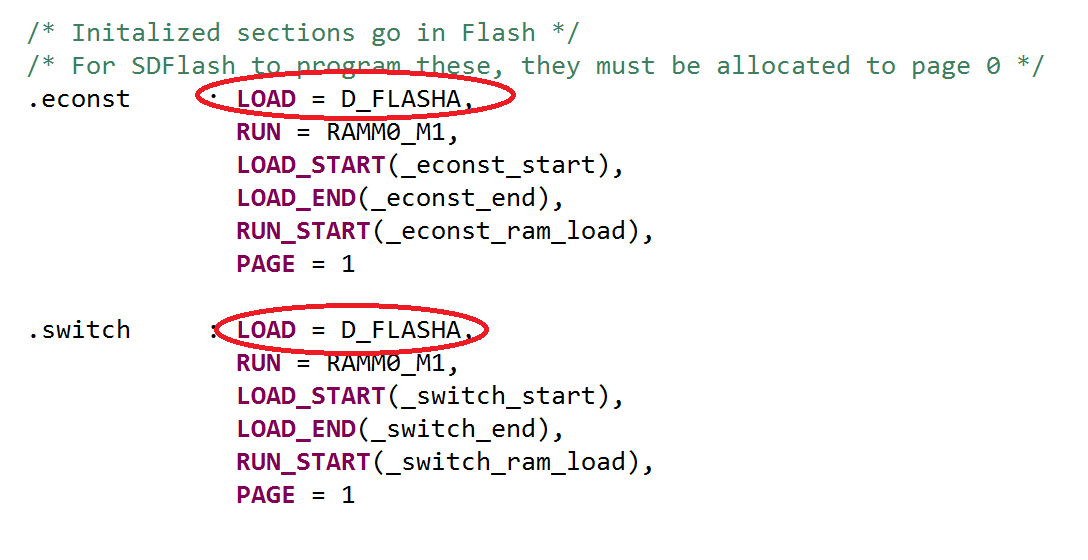

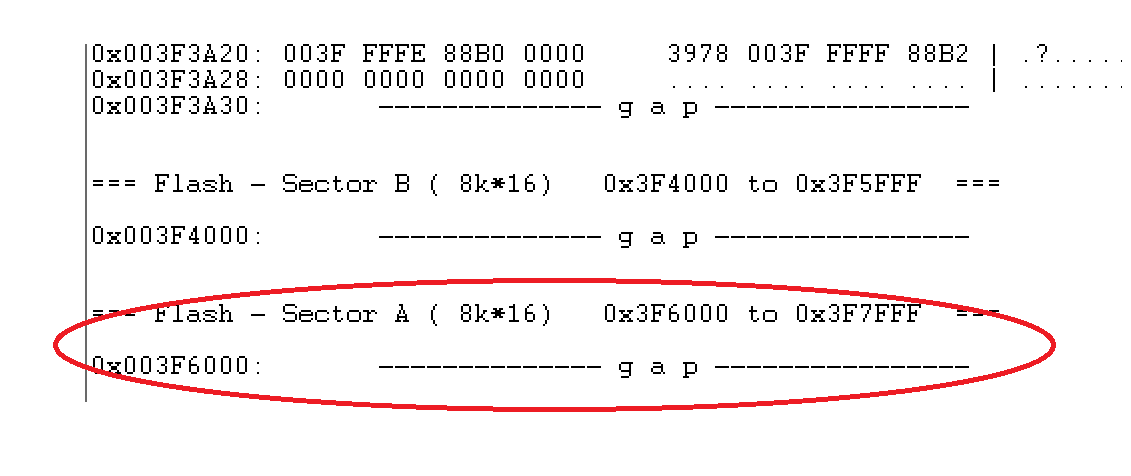

When got .hex use CCS's post-build steps(Create flash image: Intel-HEX), can get the .hex file, but in Flash section A, can't find any data! I look their CMD file and Map file, all showed that there were some data in Flash sector A, but can't find it in .hex file. please kindly find CMD and map and .hex pic as blew:

As pic above, you can see that from map and CMD file, that Flash A have some data, but .hex file lost Flash A's data. Why? Would you give me some suggestion? thanks!