Hallo,

we use 28335 for ec-motor control. We are in production since 13 month, and have a problem with about 5% units.

Diagnose:

We use the High-resolution PWM'S for a 3-phase ec-motor with FOC control. All is working well.

After several turns with fixed motor current to detect encoder reference, we use fix vectors to detect the magnet system and switch then

in the "normal" FOC mode. At this time at 5% of the PCB's with 28335 the EPWM outputs were set to zero. This occurs only if the PCB has operating temperature of about 30-35 degrees. When we cool the PCB area under the 28335, switch on and off, the error disappears.

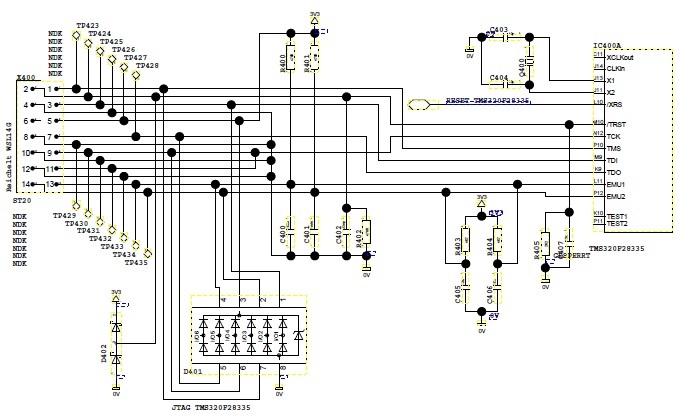

When I contact the 28335 with the JTAG debugger (Blackhawk) I can also restart the system correct and the EPMW output are in normal state when starting the FOC (duty cycle 50%).

When switching the motorcontrol from magnet detection mode to FOC mode, the EPWM outputs or any 28335 register will not be touched.

We have examined the solder point of the 28335 BGA with X-Ray technology, no result.

My question:

Is there any simular bug known?

Is there a 28335 PIN which can possibly cause this (e.G. a jtag pin)?

would be nice to here from anybody!