Hi!

I am using the TMX320F28377D device (since the TMS320F28377D has not been released to production), and I had 3 questions.

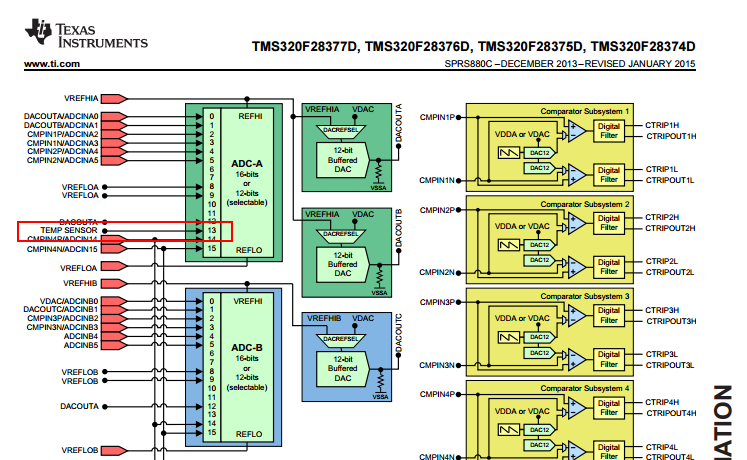

- Internal Temp Sensor

I'm using the internal temperature sensor, and there is very little documentation about its use or accuracy. The TI support page states some dies may be +/-10 degree accuracy, and some older dies might be +/-20 degrees, but it does not specifically define which die versions these are. The Slope is unspecified, but the support pages also state it should be 250 degreesC per volt. Even with this information, the results are inconsistent between my boards. Does anyone have any additional information about this?

2. ADC Sequencers

I am using most of the ADC channels, at a fairly high rate, and I have the ADC sequence synchronized to the EPWM. After the sequencer is triggered, I have to wait ~2us for all 4 sequencers to show as complete – by verifying all 4 ADCBSY flags; however even after all 4 sequencers show as not busy, I still have to wait ~1us to read the ADCs otherwise the readings are erratic. I could not find another method for insuring the ADCs were complete except using ADCBSY, however they are not truly complete because I still have to 1us to read them. Does this extra 1us make sense to you, or should I be using another flag to insure the ADCs are complete?

3. Switching between ADC Modes (12- and 16-bit modes)

I'll be using the ADCs in 16 bit mode for some readings and in 12 bit mode for others, but switching the ADC mode before each reading produced erratic results. To fix this I simply left the ADCs in 12 bit mode. Do you know if there is a problem with switching 12/16-bit modes between readings?

Thank you for your help in advance.

James