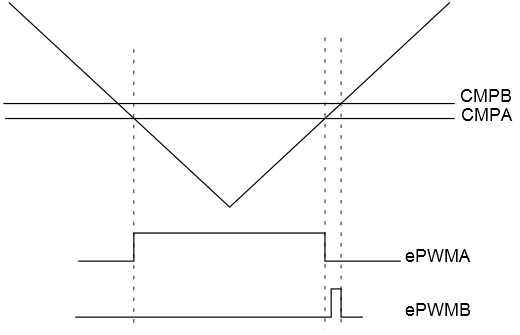

I need to generate a bootstrap charging pulse for a synchronous buck regulator, implemented using F28335 processor. To do this, I need to generate a small pulse on ePWM1B channel, right after the pulse on ePWM1A has ended. Something like this:

Is there any way to generate something like this from the ePWM module on the processor? I have tried a few dead band settings and set/clear settings for ePWM1A and ePWM1B, but have not been successful. Please note there is a small dead time between the ePWM1A pulse and the bootstrap pulse on ePWM1B. The dead time has must be generated to avoid shoot through in the converter.