All,

MotorWare version 15 is now available for download

-

Support for new 45V/15A BOOSTXL-DRV8305 (with LAUNCHXL-F28027F; LAUNCHXL-F28069M support to follow in next release)

-

Modulation Change for all projects

-

Changed the range of the USER_MAX_VS_MAG_PU variable (and hence gMotorVars.OverModulation) so outputs match the scaling of the PWM duty cycles

-

Old Range: 0 to 1.333 New Range: 0 to 0.666

-

-

Proj_lab10 modifications to use new over-modulation technique which improves high duty cycle current sampling for more stable control at high speeds or high loads

-

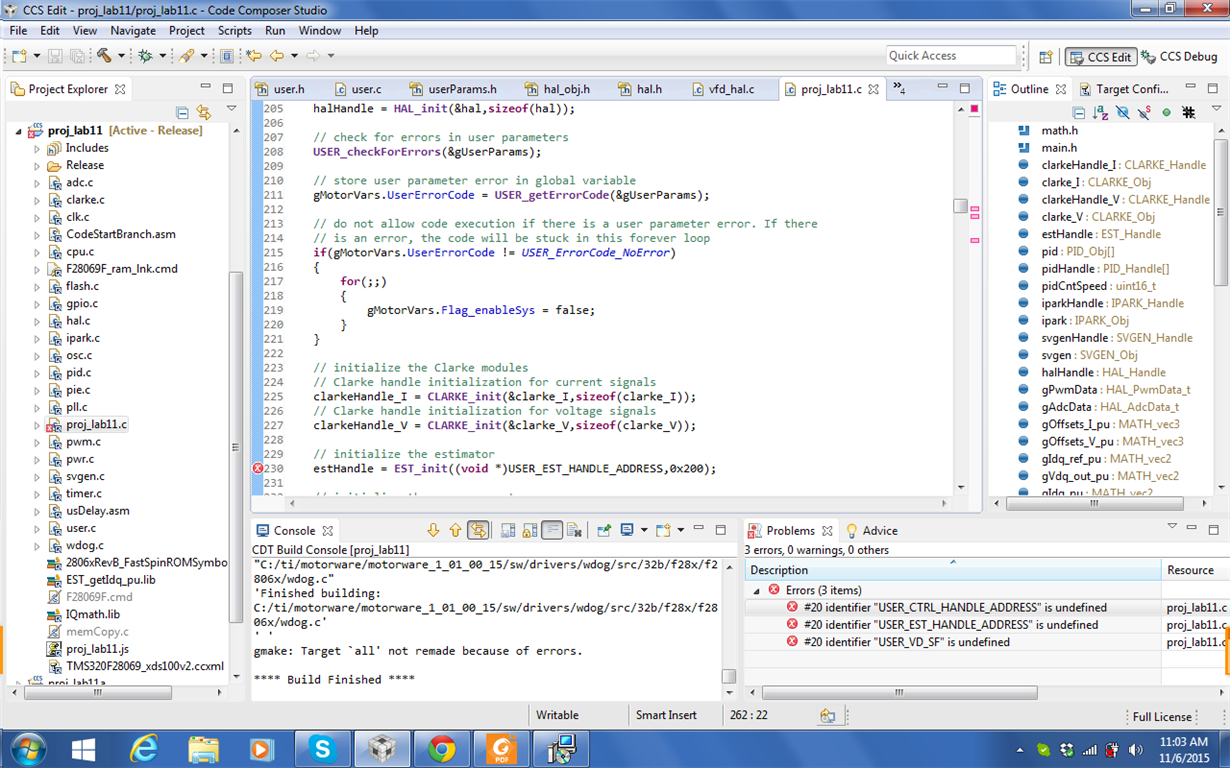

Proj_lab11, 11a: simplified code without abstracted CTRL functions. Makes it easier to customize the control system while still using the FAST observer.

-

Proj_lab11b: low speed vibration compensation example, ideal for compressor applications

-

Various minor fixes

-

See MotorWare.exe Resources à Revision History for full list

We are starting work on version 16 with a scheduled release in December. Items we are prioritizing:

- Dual motor proj_lab example for LAUNCHXL-F28069M

- Extend support for BOOSTXL-DRV8305EVM to LAUNCHXL-F28069M

- Hall sensor start-up with transition to InstaSPIN-FOC proj_lab example

- Flying start proj_lab example