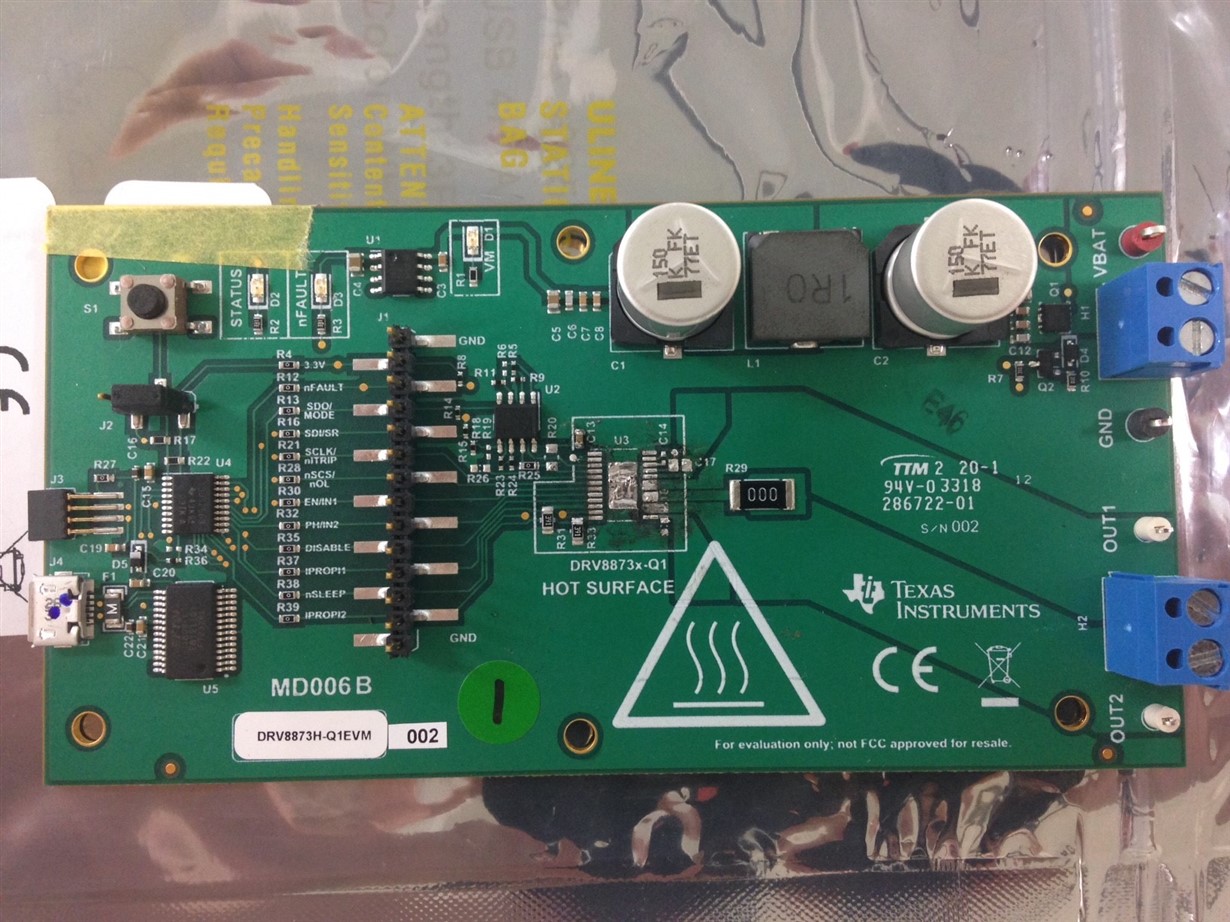

Other Parts Discussed in Thread: DRV8873S-Q1EVM, DRV8873H-Q1EVM, DRV8873

Dear Expert,

Thank you for your special support everyday.

My customer is considering this product.

I received the following question from the customer.

<Status>

During EVM evaluation,

When changing [Wake] of GUI screen to Disable → Enable,

The motor behaved wrong and the driver was damaged.

Since it is not time when [MotorControls] was set to START,

we also suspect a malfunction of the tool.

<Question>

-Is there timing and conditions for overcurrent detection function not to operate?

-Is there a similar report so far?

Best Regars,

Fukazawa

Best Regars,

Fukazawa