Other Parts Discussed in Thread: BQ25601, BQ25600D, BQ25600

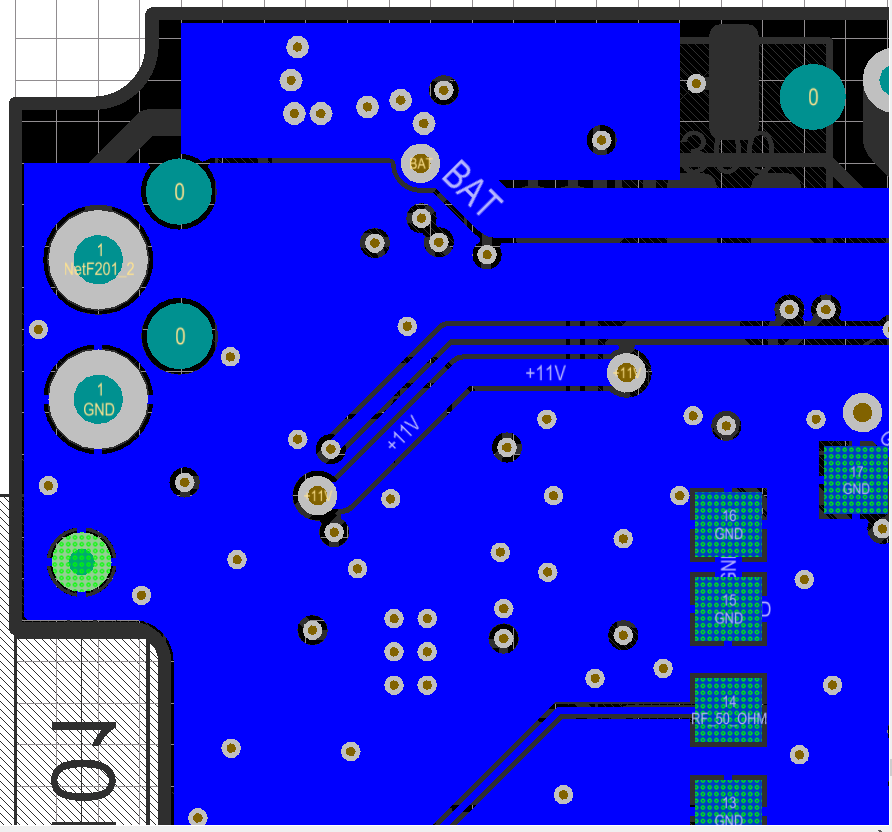

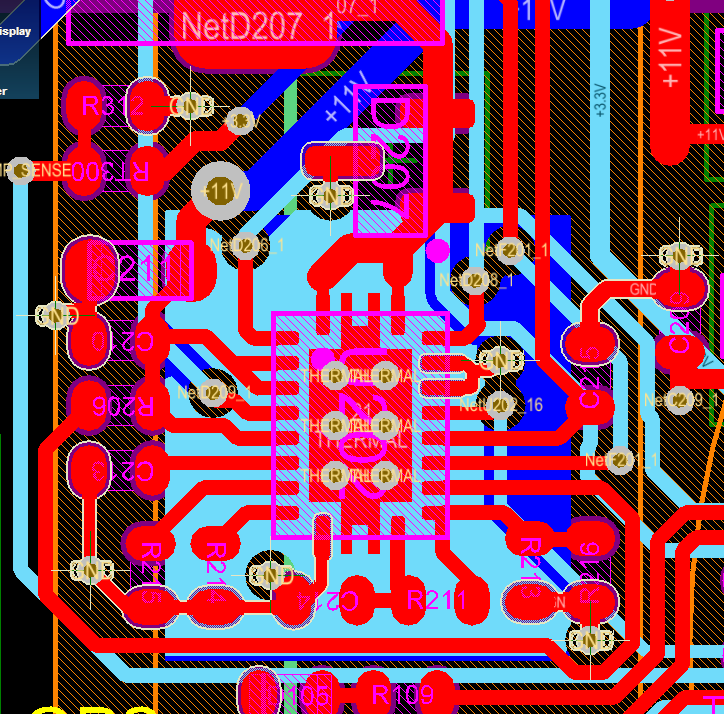

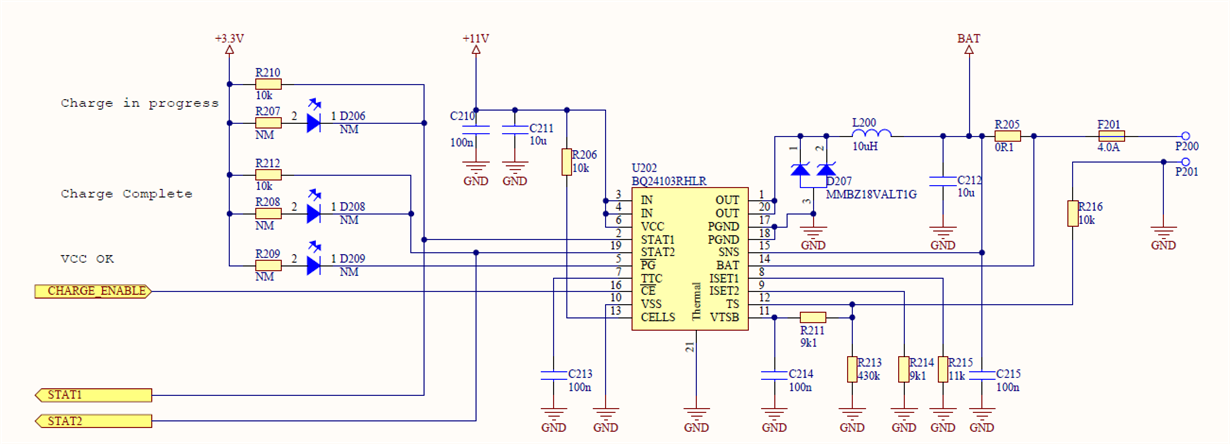

We have manufactured more than 30k units of our product using BQ24103.

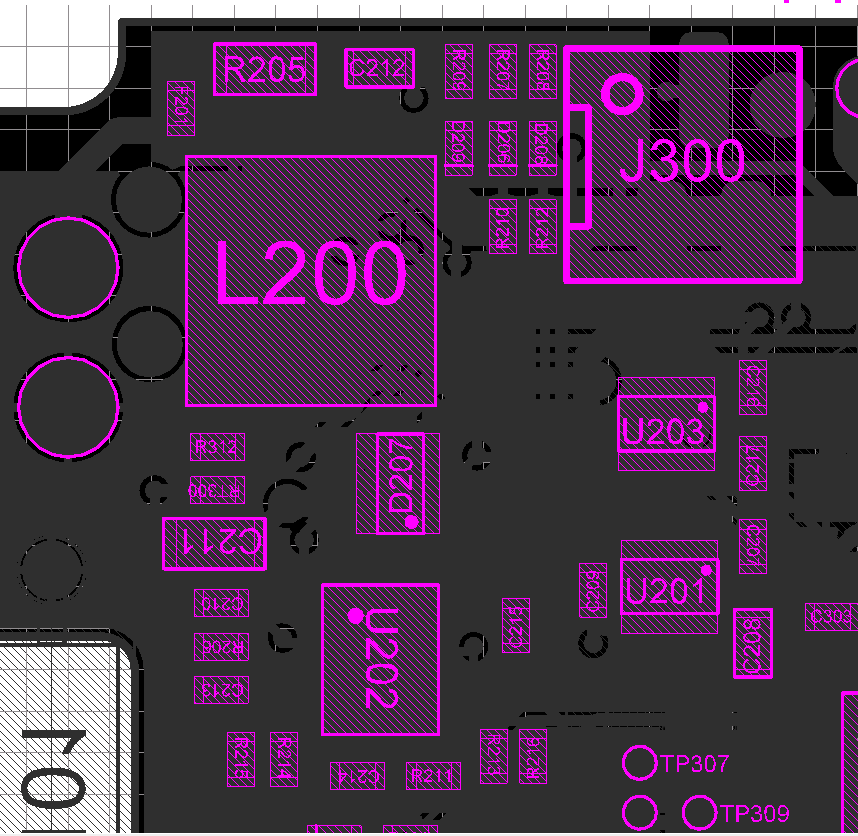

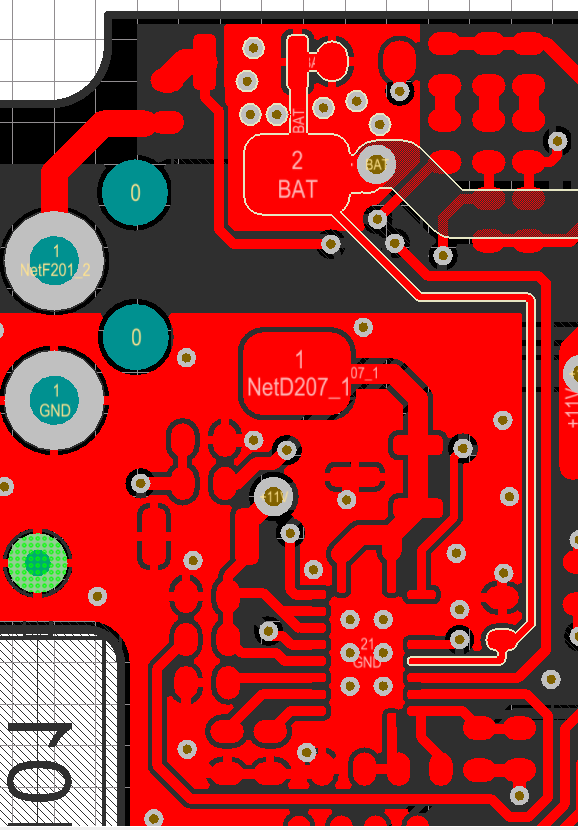

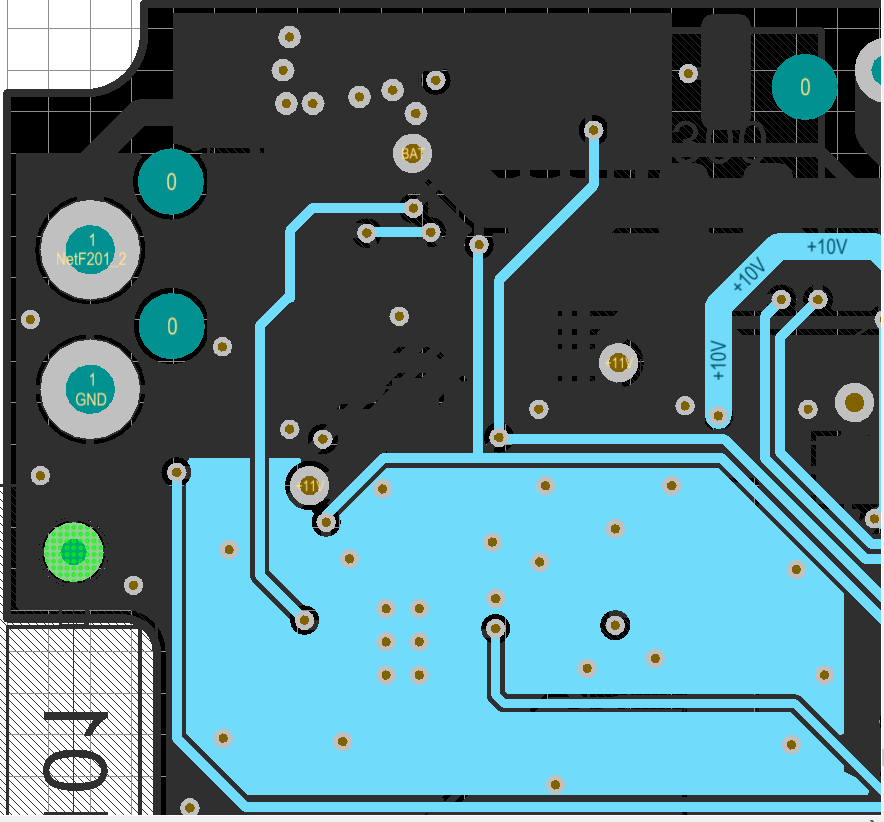

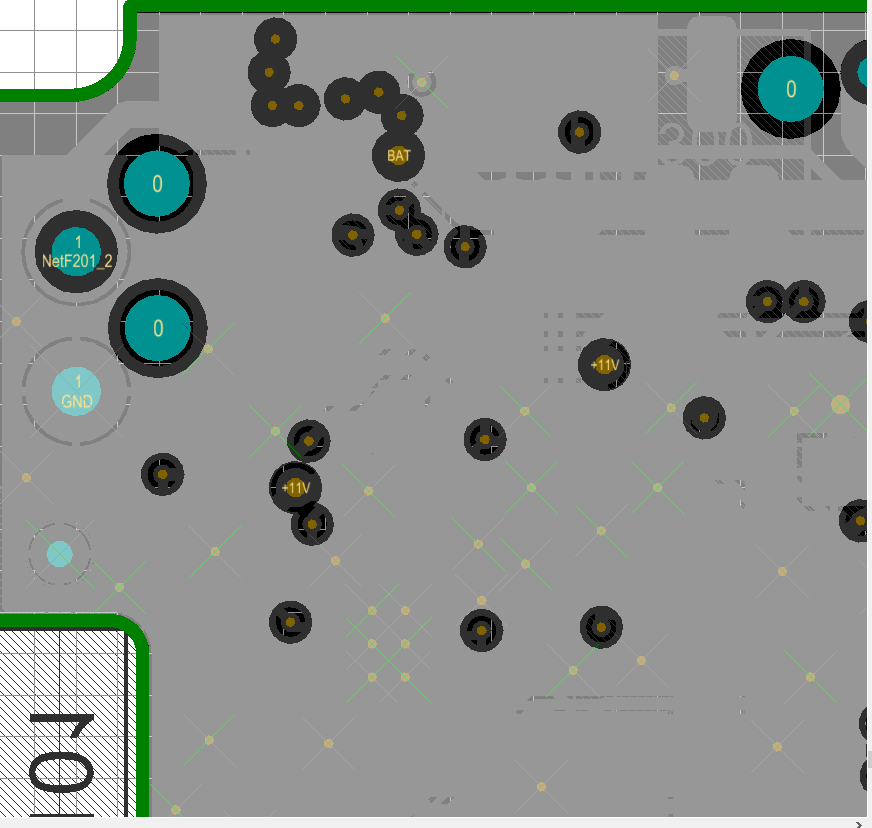

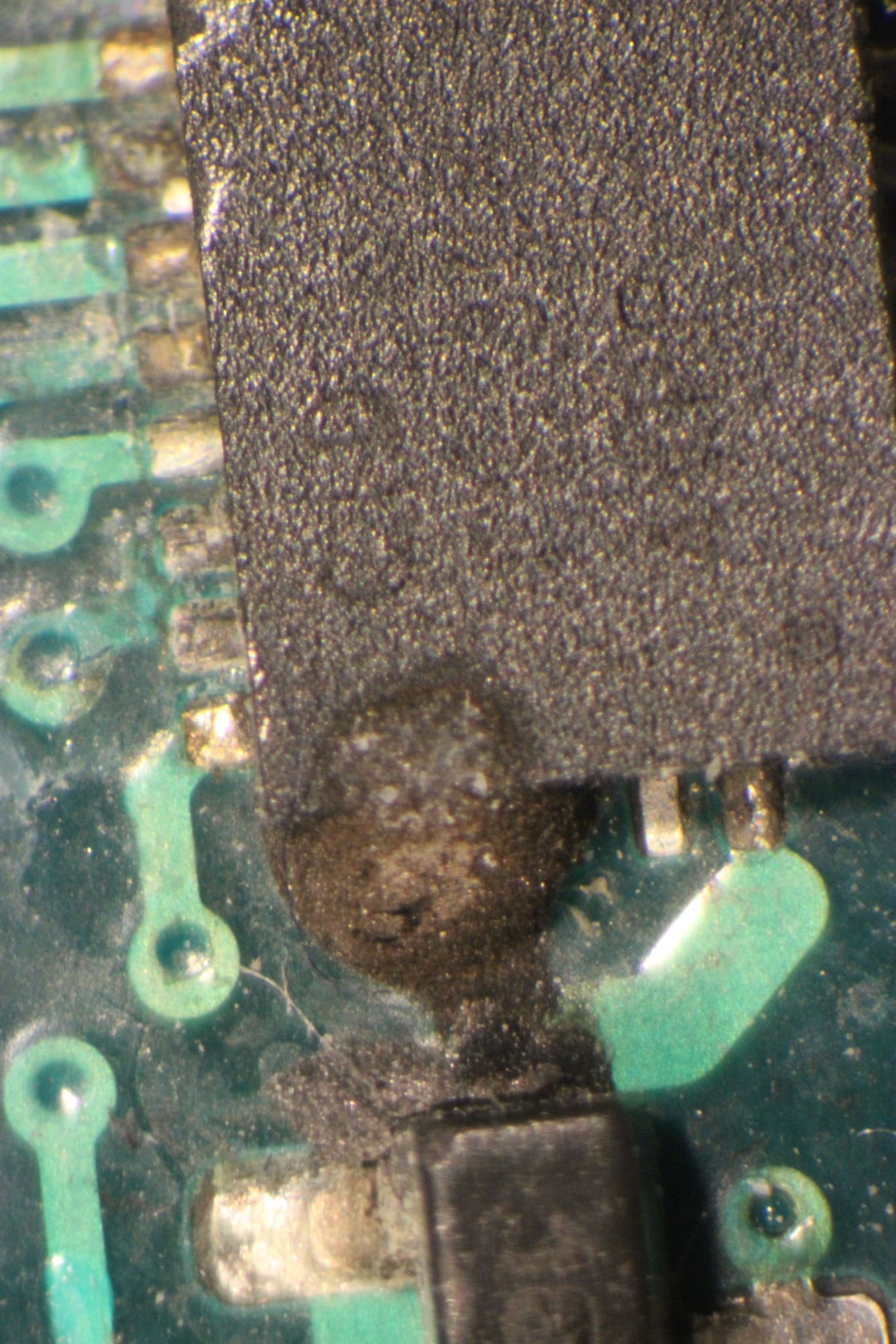

There has been detected a charge error on some units and by investigating these units it is shown that the charging circuit BQ24103RHLR is broken. It looks like the IC is overheated and that a compound has leaked from the IC and formed a bubble, as can be seen on the attached picture. Schematics is also attached.

Initially we do not expect that there is an issue with the IC, but we are very interested in finding the reason that this can happened. Especially since the circuit has over temperature protection.

Initially we do not expect that there is an issue with the IC, but we are very interested in finding the reason that this can happened. Especially since the circuit has over temperature protection.

The product is molded and thus there is hard to search for the root cause. The molding must carefully be removed and this is a time consuming and difficult process that might inflect new errors on the board.

Q1. Have you seen this symptoms before?

Q2. Do you have any suggestion on what might cause this error?