Other Parts Discussed in Thread: BQSTUDIO, GPCCHEM, EV2400, BQ34Z100-G1

Hi, I got some problem on bqstudio again.

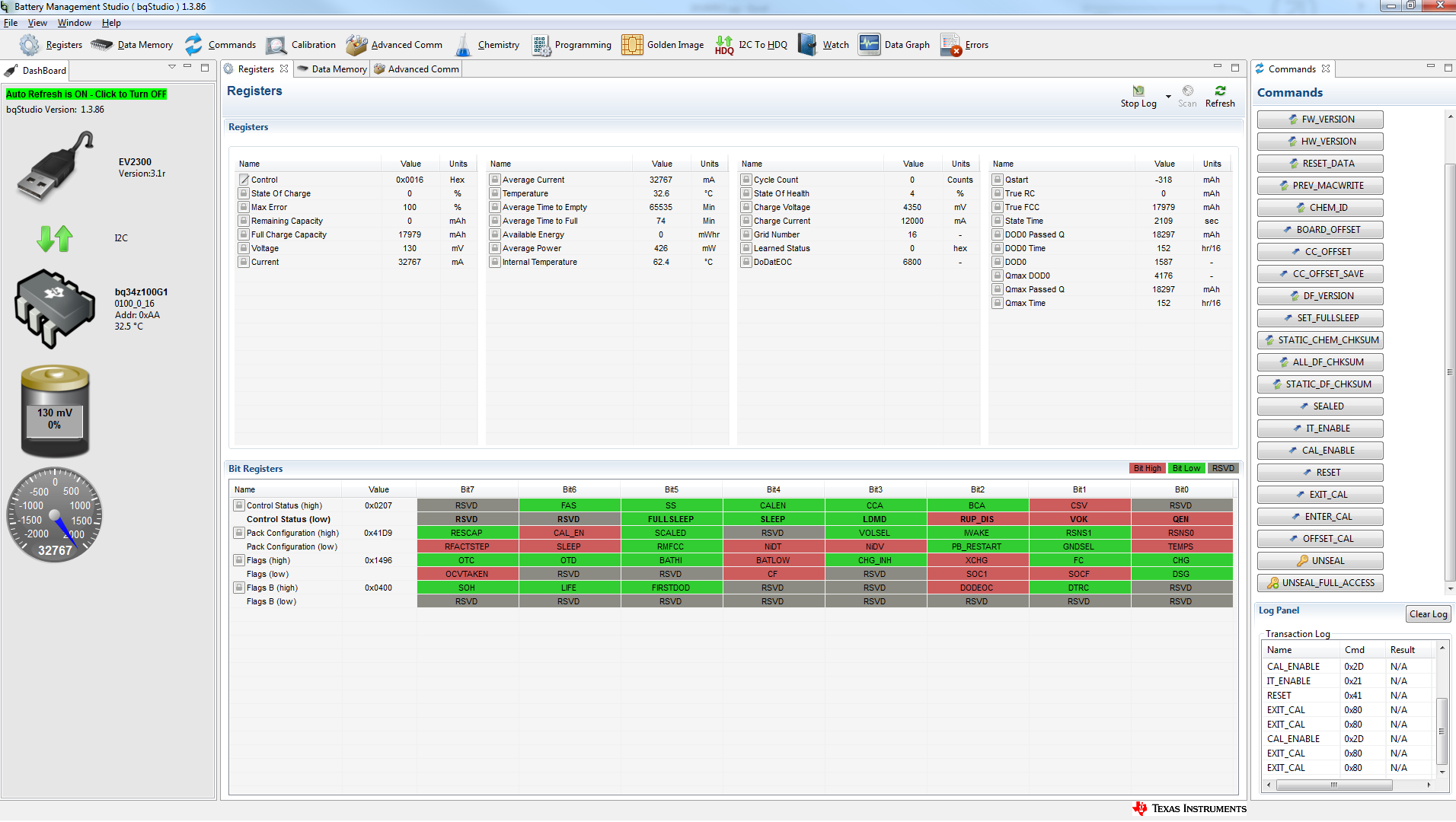

Here's my setup

Battery Samsung ICR18650-30B (8*3000=24000mAH) (Connected in parallel)

I tried to charge and discharge several time, do as the reference manual suggested.

But i can't update the status at all.

I definitely have enough rest time, charge to full and discharge to empty.

Is there any possible factor that can affect learned status update?