Other Parts Discussed in Thread: LM317, , TPS65132

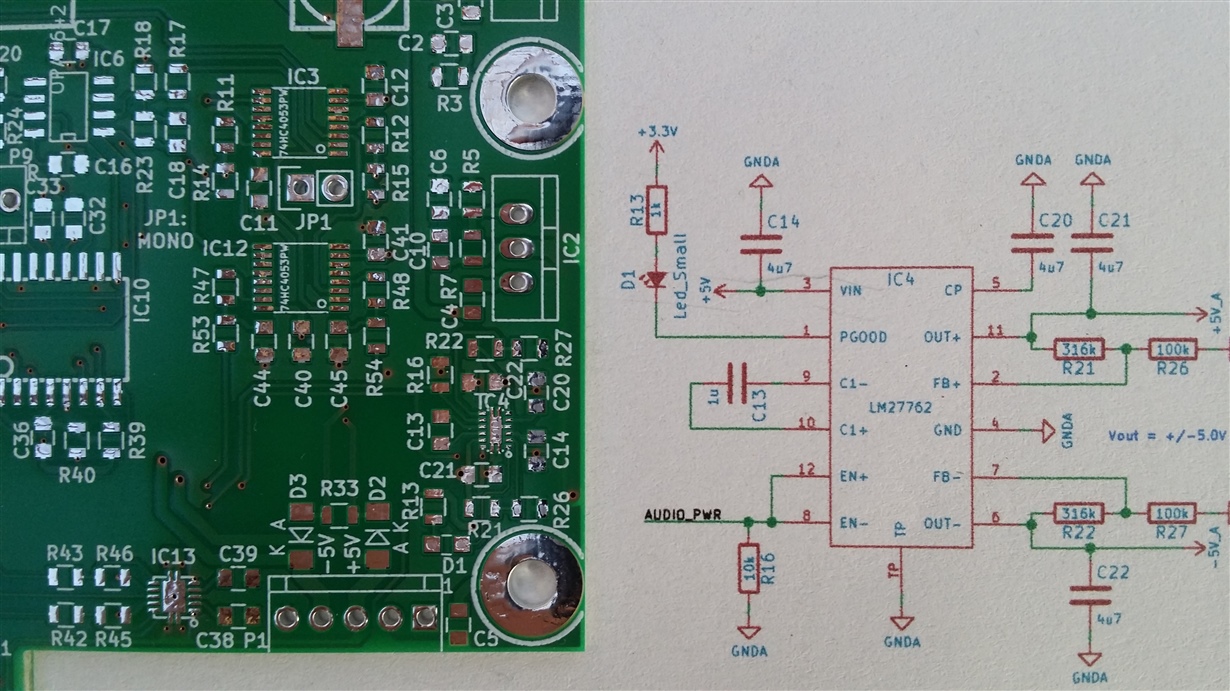

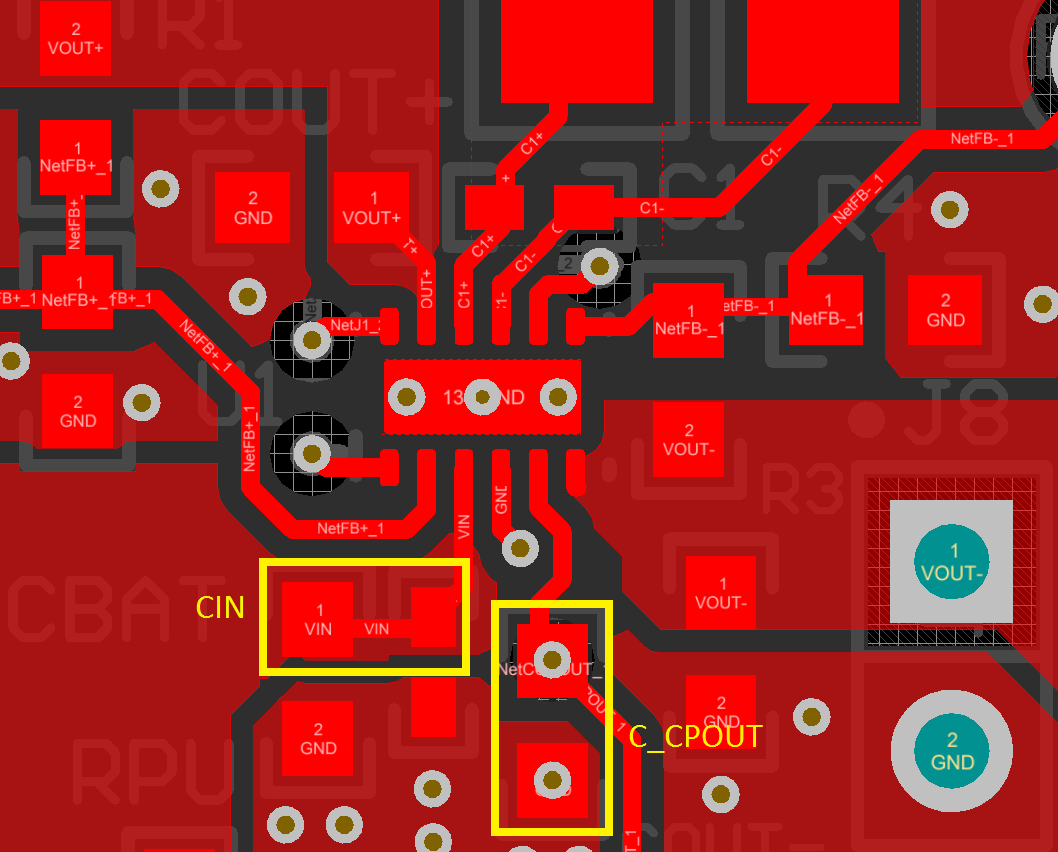

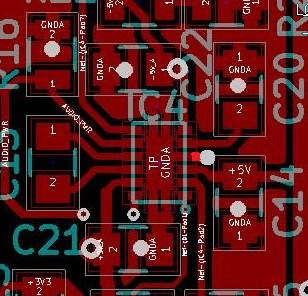

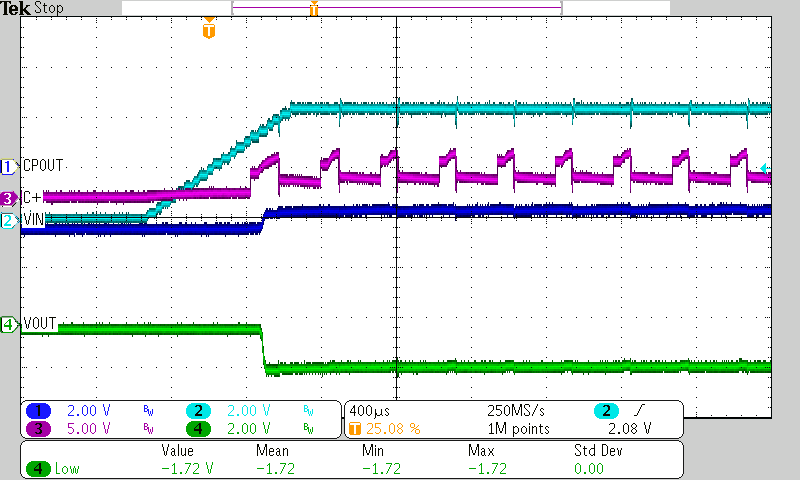

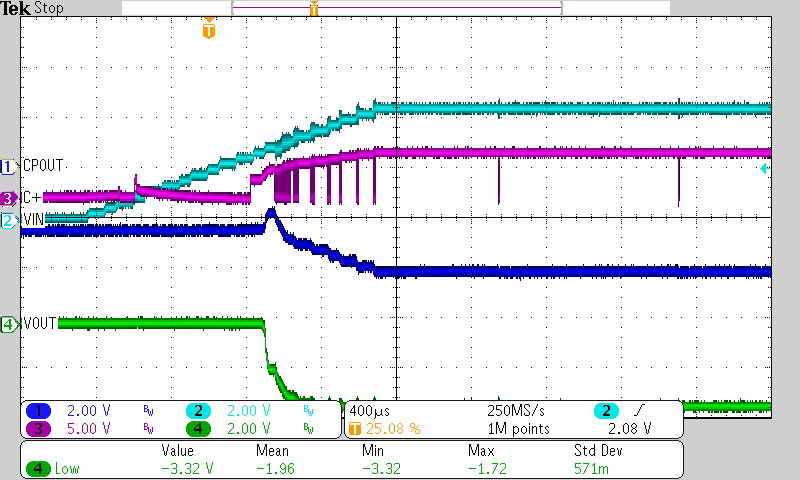

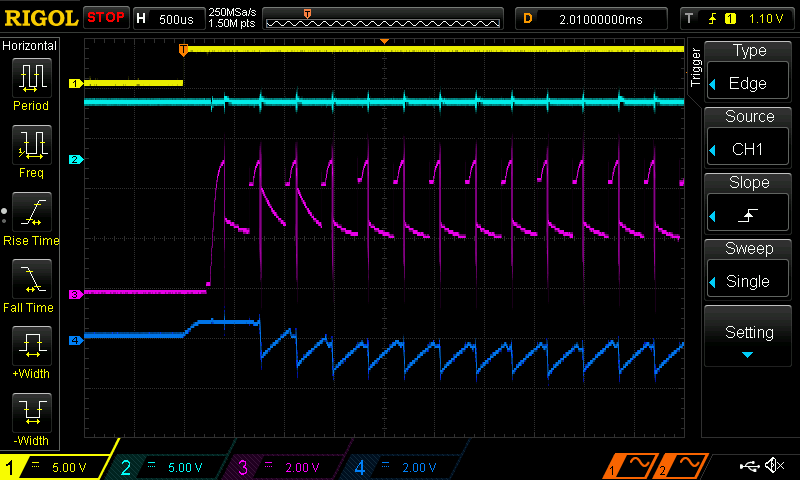

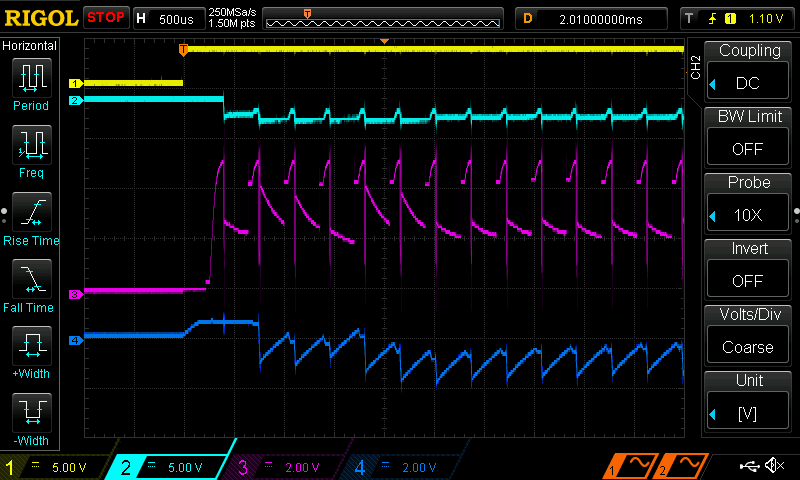

Hello, I'm having a little problem with the power supply for my audio design (see attached schematic). The idea of the power supply design is, to use a linear regulator (I use LM317T) to stabilize a DC input voltage to 5.3V. From the +5.3V I want to generate a +/-5V audio power supply for the analog circuit. The DC input voltag should be +8V up to +15V. The design works if the DC input voltag is about +7.7V ... +8.3V (stable +/-5V analog output voltage, LED is on) but if the DC input voltage is higher, the LED connected to PGOOD does not turn on and the negative output voltage does not go to -5V. It looks as if the LM317 output cannot cope with the load represented by the LM27762. Any idea what goes wrong?

Andy