Hi Team,

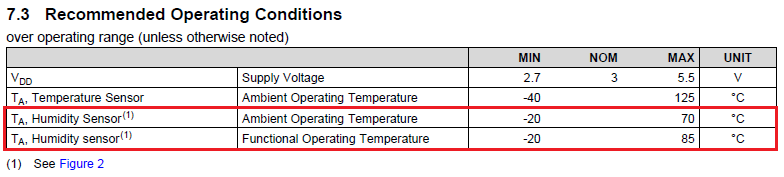

Could you clarify a difference between "Ambient Operating Temperature" and "Functional Operating Temperature"?

Best Regards,

Yaita / Japan disty

-

Ask a related question

What is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.