I am developing a product that incorporates the LDC1612 to monitor the inductance of a coil. The coil itself doesn't meet the parameters to work with the LDC, so I am using it in series with a fixed inductor as per the instructions usually given on these forums. The coil is approximately 0.3uH, and it is in series with a 4.7uH inductor at the moment. The tank capacitor is 220pF.

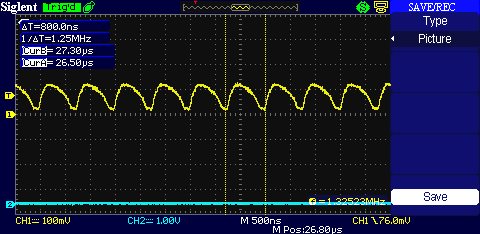

When I use this setup on the LDC1612EVM, it works perfectly. Trying it out on my prototype board, it is oscillating the tank system at ~615kHz, which is both the readout I get from the device and visually confirmed with my oscilloscope. My settings for the LDC1612 are as follows:

//RCOUNT_CH1

0x09: 0x04D6);

//SETTLECOUNT_CH1

0x11: 0x002B);

//CLOCK_DIVIDERS_CH1

0x15: 0x1002);

//ERROR_CONFIG

0x19: 0x0000

//MUX_CONFIG

0x1B: 0x020F

//DRIVE_CURRENT_CH1

0x1F: 0x9000

//CONFIG

0x1A: 0x4001

The above only includes CH1, which is connected to the sensor in question. CH0 is connected to a separate system that is working fine at this point, and uses similar settings. I have 0x1A set to only read CH1 at the moment while I debug this part of the system. The deglitch is set to 33MHz above, as I was trying out different deglitch settings. I get the same results with ALL values for deglitch.

What could possibly be making this tank oscillate at 615kHz? I can take the 0.3uH coil from my prototype board to the EVM and get the correct readings, but no matter what I do it always oscillates at this frequency. I can't even begin to figure out what is happening so far. Any help is greatly appreciated!