Hello TI !

Is there any information about how the input parameters of this part react to change of humidity level?

Maybe graph like this?

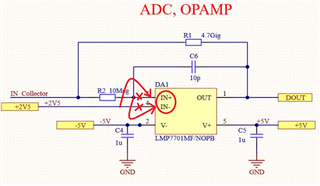

I have a problem with floating output with hum level near 80% and above. And i want to find out this is the problem with pcb tracing or with LMP7701 itself.

Best regards,

Ilia