Other Parts Discussed in Thread: REF200, INA326

Hi Team,

Can you have a look at the following customer inquiry?

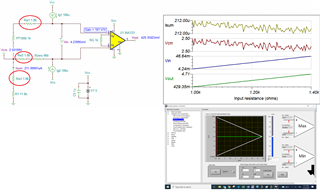

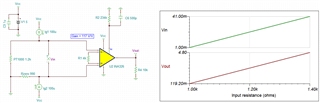

They have simulated their application in TINA and are seeing some discrepancies.

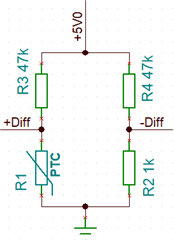

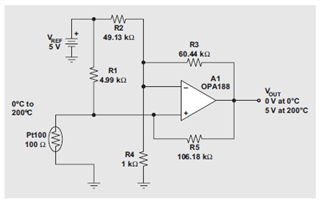

Basically, we now have a functional circuit with the INA333.

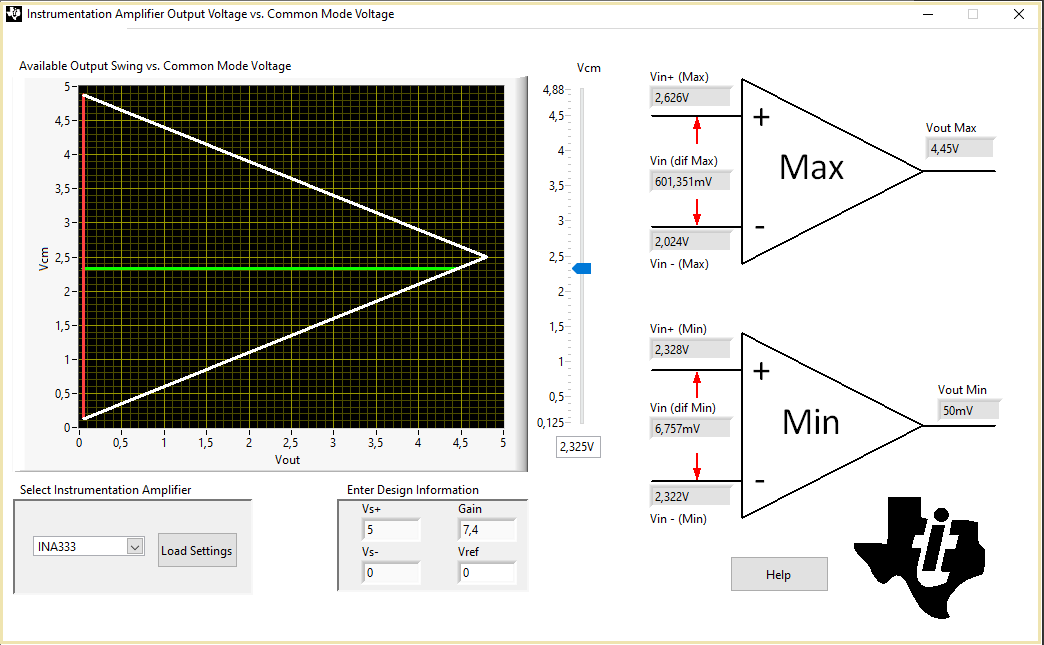

The offset voltages at the inputs are 2Vdc.

Nevertheless, the simulated results are next to the expected values.

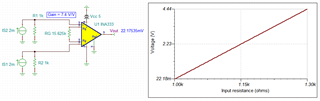

The gain factor is a low 7.4 and should give 4810mV instead of 4664mV at the output with a differential voltage of 650mV, 146mV too low.

A differential voltage of 600µV should result in 481.7mV at the output instead of 481mV, i.e. 700µV too much.

Shouldn't the amplification factor be more linear with this circuit?

Thank you,

Franz