Hello experts,

1. On the board you can measure the phase voltages. You can display these voltages or take them for a sensorless control. Are there any other uses for the measured phase voltage? Can it be used to monitor faults, for example?

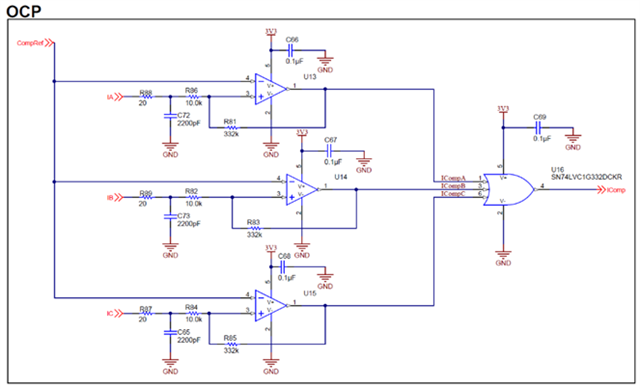

2. There are two methods implemented on the board for overcurrent protection

a. hardware-method with with 3x TLV320x (see picture)

(BOOSTXL-3PhGaNInv Schematic (Rev. A)

b. software-method: phase currents -> AD converter -> CMPSS -> (trip)-EPWM

It is obvious that the first method is more expensive. But in case of overcurrent the currents can be switched off faster. The second method is cheaper and also very elegant. But is this method also fast enough to switch off the MOSFETs in case of a fault? And of course, if the second method works safely, it is the favored method for everyone. Are there perhaps situations where one should definitely use the first method?

3. In order to detect shorts of the motor windings to ground or to each other, it is necessary to measure the supply-side and/or return-side DC bus current. But on the board it is not possible to measure this currents. Is there perhaps another methods from TI to determine this currents indirectly in order to detect the mentioned short-circuit fault?

Many thanks in advance and best regards

Bui van Linh