Hi team,

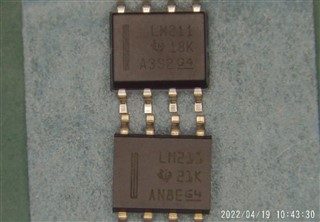

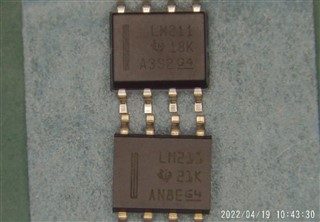

The mold shape of LM211DR has changed, but this change has not been announced.

Please explain why there is no PCN letter.

I assume it is related to JEDEC standard.

Both assembly sites are in Malaysia.

Regards,

Takashi Kamijo

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Hi team,

The mold shape of LM211DR has changed, but this change has not been announced.

Please explain why there is no PCN letter.

I assume it is related to JEDEC standard.

Both assembly sites are in Malaysia.

Regards,

Takashi Kamijo

Hello Takashi,

I see there are two leadframes in use in use in Malaysia - the standard leadframe and the newer roughened leadframe. The different leadframes may require different molds. Both use the same base leadframe material and mold compounds.

It is a little difficult to tell, but the upper "18K" looks to be the older "smooth" leadframce (shiny), and the lower looks to be the roughened (not shiny) leadframe. There may be a mold ID on the underside of the package.

There was a general PCN in 2021 about the change in the labeling font, to the new "OCR"-friendly font across a wide number of devices (which is visible on the bottom "21K" device).

Both packages should meet the "D" package drawings width and height specifications (within JEDEC MA-012AA).

SOIC (D) | 8

My guess is that a change in the leadframe style (not materials) may not be notifiable as the base materials did not change and it is still within the package specifications. I will double check.

Hi PaulM-san

Thank you for your reply.

I know PCN # 20211123004.0.

But the Pin One marking hasn't changed, so I don't think this PCN has anything to do with it.

There is a possibility that two mold styles have been set in Malaysia from the beginning.

If there was a mold style change, please tell me why TI didn't notify me of this change.

Regards,

Takashi Kamijo

Hello Takashi,

I does look like two different molds are being used. The lower package does not have a defined pin 1 side bevel and there is less "flashing" between the pins.

Again, I am confirming if changing the leadframe is a notifiable PCN event for a general purpose, catalog (non-automotive) device.

Hi PaulM-san

I understand.

I'm waiting for your answer.

Regards,

Takashi Kamijo

Hello Takashi,

I received confirmation that changes in the mold fixture does not trigger a PCN for commercial catalog devices.

Other than the leadframe "roughness" and internal structure, the materials (mold compound, bond wires, mount compound, leadframe base material and plating) did not change.

So you did not receive a PCN because it was not required. The roughened leadframe is being rolled-out across TI, so you may be seeing this on other devices in the future.

Hi PaulM-san

Thank you for answering.

TI's PCN standards are published on the following website.

https://www.ti.com/support-quality/quality-policies-procedures/product-change-notification.html

And there is the following explanation.

------------

TI complies with the requirements for timely notification in J-STD-046.

Consistent with this industry standard, customers will be notified of major changes which affect the form, fit or function, or adversely affect quality or reliability of the product.

------------

Is it okay to understand that this case complies with the JECED standard (J-STD-046)?

I need to explain to the customer.

Regards,

Takashi Kamijo

Hello Takashi,

Though the leadframce changed slightly internally, it did not change the external Form, Fit or Function. It is still within the "D" package drawing specifications and electrically there is no difference. This is considered a minor change from the customer perspective.

The new "roughened" leadframe actually improves solderability and package lead-pull strength as it increases the surface area (like roughening-up a surface before gluing). So it is an improvement!

So, yes, it complies with J-STD-046.