Part Number: INA239

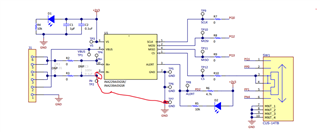

(1) when I use INA239EVM to measure current, the settings are as follows:

If the conversion time bit is set to 50us and 100000 sampling points are stored in excel, it will take about 5s. but i think excel stores100000 very quickly, and the time is less than 5s, So i want to ask INA239 how long is the interval between the two sampling points, and how do i store data in excel for a longer time.