Part Number: OPA549

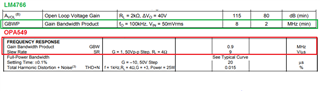

Other Parts Discussed in Thread: LM4766

OPA549をブリッジ・アンプ回路で使いたいと考えています。

LM4766のデータシートにある応用回路を参考に使用することを考えていますが

使用可能でしょうか。もし使用可能であれば注意点があったら教えてください。

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Hi Shuji-san,

もし使用可能であれば注意点があったら教えてください。

I need to know the detailed design requirements in your application. For instance, what is application? What are the type of load, output voltage swing, required driving current, etc.? It is doable, but the simulation may provide better understandings, if we are able to meet the application requirements.

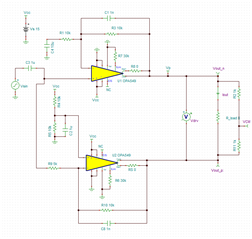

Enclosed is a quick example, which I made it up. If you have additional questions, please let me know.

OPA549 Bridged Drive 01192023.TSC

Best,

Raymond

Hi, Mr.Raymond.

Thanks for your answer.

I use this amp to run current through the coils of a voice coil motor. Right now I am using one amplifier to drive it, but I would like to use a bridge circuit to drive a larger current.

Type of load: coil (10Ω)

Output voltage: ±24V

Output current: 4A

Question.

Why does the reference circuit show the output signal (Vp) of U1 as the input signal of U2?

My thought was to use the same input signal to create a bridge circuit using an inverting and non-inverting amplifier circuit.

Regards,

Shuji

Hi Shuji-san,

Are you driving the speaker up to 20kHz in audio application? How critical is the audio application? OPA549 may not be well suited to drive an audio speaker application.

Is output voice coil is 24Vpp? If it is 24Vpp, each half of power amplifier will responsible to driver 12Vpp in amplitude. Please let us know more about the audio application.

Best,

Raymond

Hi, Mr.Raymond.

Thanks for the advice.

I will not use it for audio applications.

I'm thinking of using it from DC level to about 10 kHz, so the gain bandwidth is fine with OPA549.

I will use 48Vpp for the voice coil.

Regards,

Shuji

Hi Shuji-san,

Raymond is out for the Chinese New Year. I'll try to follow up on these posts.

Looks like you have a single-ended input that you need to convert to differential to drive a high power differential (BTL) coil. Raymond used the output of the first stage, and fed to an inverting stage, to create the inverted signal. For this case the total load in the input source is reduced. The downfall is that the phase of the second inverting stage will not maintain exactly 180 degrees as the bandwidth goes up, which will then lead to differential errors at higher frequencies.

Phase errors will result in a common mode signal. Ideally, when there is a perfect 180 degree phase difference, then the common mode gain is zero or very low. As the phase errors increase, then the common mode voltage increases.

In the circuit below, I measured the common mode voltage with a simple resistor divider. When measuring the common mode gain between the two circuit types, there was lower common mode gain for the circuit below (using an inverting and non-inverting stage), mainly due to the phases maintaining 180 degrees..

However, this is a slightly larger solution because of the additional R/C components.

If your system is sensitive to these differential errors, the ideal solution would be to use an Fully-Differential Amplifier to convert the single-ended solution to differential, then drive the load with buffer-connected OPA. However, many times this is not a critical concern, so it is possible both Raymond's circuit and and circuit above would be fine.

Regards,

Mike