Hi team,

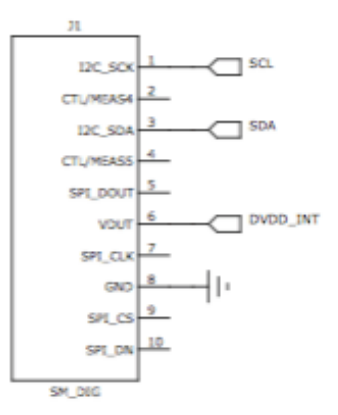

My customer want to access three INA226 device on their own PCB board, they only reserve I2C data and clk pin for comunacation.

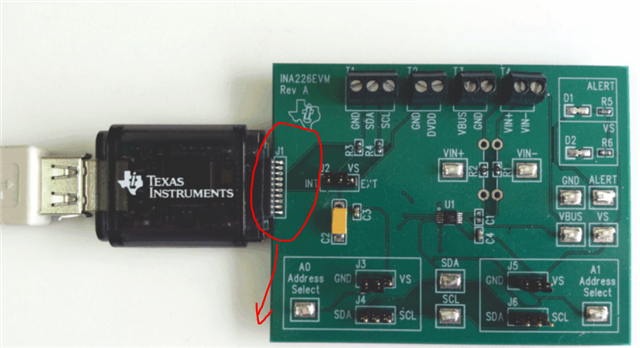

Now I have a INA226 EVM avalable, could you give a detailed guide about how to communication with INA226 device via GUI?

PS:

I notice there is a new GUI and EVM versionB available, the current EVM i have is the version A.

Best regards

Fanbin