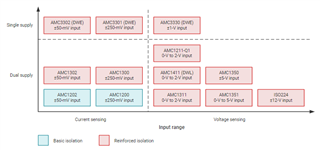

Other Parts Discussed in Thread: TLC272, , INA781, INA780, OPA187, OPA2187, TINA-TI, REF35, OPA2182, OPA593

Hi All,

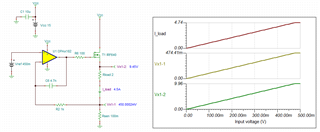

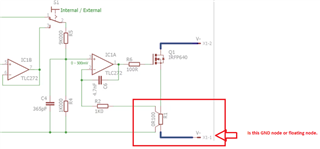

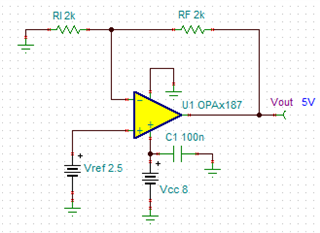

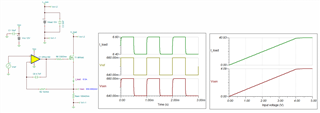

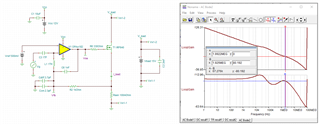

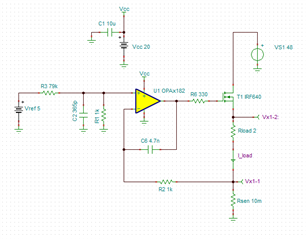

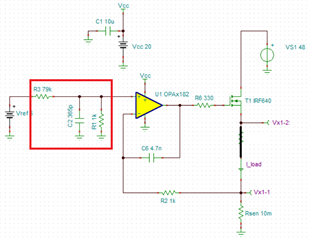

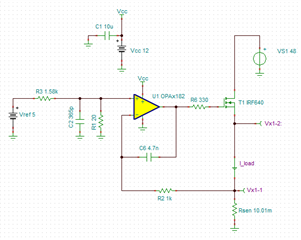

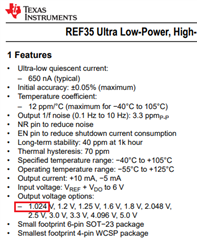

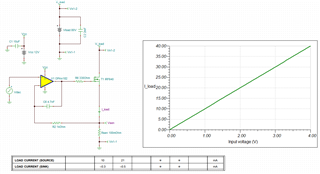

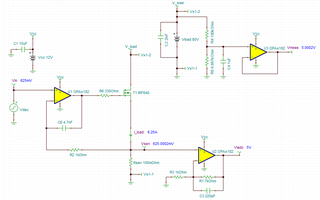

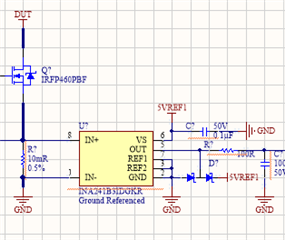

I am currently working on a high precision, high current electronic load, and I am curious if I use the OPA182IDBVR will I gain more precision in the current setting? The op-amp will be used to sense the current through a 0.1 ohm resistor and an IRFP640 n-channel MOSFET will be used in the linear region to dissipate the required current (maximum of 6.25 amps) set by a voltage on the non-inverting pin of the op-amp. I am basing my circuit around this schematic:

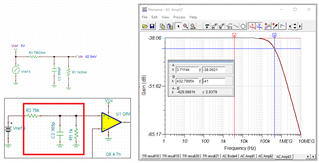

Since the OPA182IDBVR is different from the TLC272 can I still use the same values for C4 and C6 in the schematic above? If not which values do you recommend I use for the OPA182IDBVR part to keep it from oscillating?

The reason I want precision is I will be commanding up to eight of these "modules" on one board so I can pull up to fifty amps of total current. I want all eight modules to be as close as possible so when I command all eight to turn on at a set voltage I get an accurate total current draw. The electronic load will be used to find the current limit trip points from a new motor controller design and to also test for heat dissipation at rated running current from the input power supply hot-swap circuit.

Please let me know.

Thanks,

Eric Norton