Other Parts Discussed in Thread: OPA855, OPA856, OPA615, OPA860

Hi,

I need support about a new design.

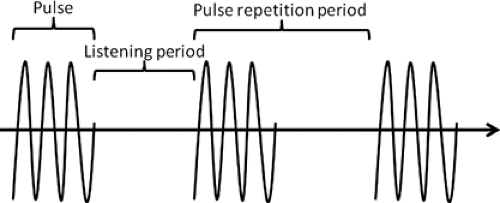

We have a photodiode integrated in a laser diode driven by a pulse train (40mA peak, 5Hz-50kHz PRF, Duration 15ns).

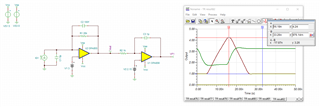

We want to design a conditioning circuit to convert the pulsed current in the photodiode in an average or peak voltage signal to be measured by an ADC of a microcontroller so to have a sort of average or peak optical power measurement.

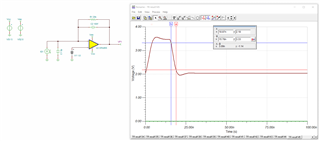

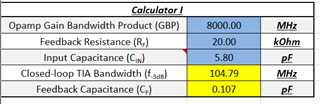

We want to use a TIA (for example OPA858) with an integrator circuit or something like that. Is it possible? Do you have a good solution?

Can you please give us support in the design?

Thanks in advance.

Best Ragards