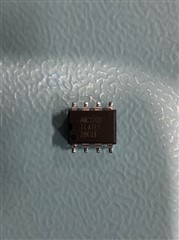

Part Number: AMC1200

Tool/software:

Hi,

we are using the amc1200SDUBR and having issues at between -30 and -40C. the devices are tin dipped before being fitted to the board and the boards are formally coated to to prevent moisture issues. The system is cycled through -40 to 75 ten times and we get random gain or noise issues so tripping our system at low temps. is this a know issue?

regards

Ross