Other Parts Discussed in Thread: REF3318

Tool/software:

Hello,

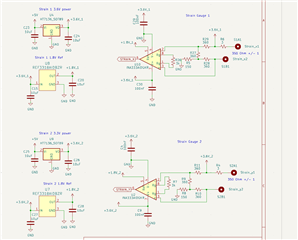

I am designing a battery powered product that needs simultaneous dual-axis strain gauge measurements, and am having some difficulty with the design. Board VDD is 3.3, though I've boosted to 3.6 for the INA333 and added a 1.8V LDO for vref. The strain gauge resistance is nominal 350 ohms, +/- 2 ohms for its operational range, and I'm using a quarter wheatstone bridge as input to the INA333. Readings are using a 12 bit ADC with a somewhat selectable input range from 0-3.3V. Accuracy and variations due to temperature will be handled in post processing using calibration data.

(note, in the above schematic, VDD is boosted to +5V, but I would prefer not to if I can avoid it)

When I assemble a single axis circuit on a breadboard, it behaves more or less as expected, but when I put two of them side by side, the readings, VO seems to be pegged to VDD, and I am suspecting that having two wheatstone bridges next to each other is just causing a resistor network nightmare.

Is there a recommended way to do this sort of thing, or a different part that would be more appropriate?

Thanks,

--

Neil